REQUEST FEE SCHEDULE

DOWNLOAD RX FORM

SCHEDULE A PICK-UP

What can we help you with today?

Popular Searches

What can we help you with today?

Popular Searches

Precision, efficiency, and esthetics define the next generation of removable prosthetics.

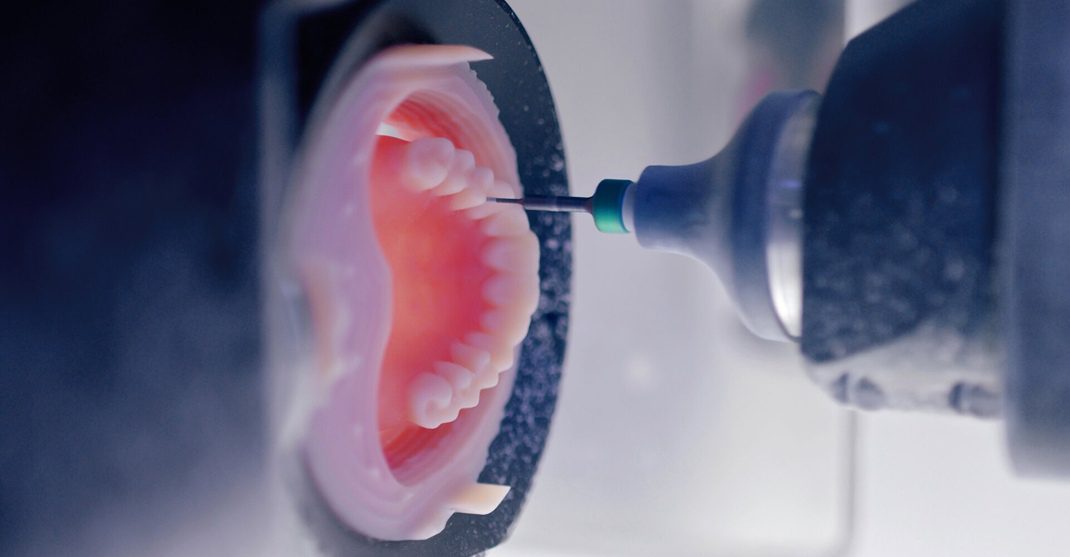

Ivoclar Digital Dentures, available through Burbank Dental Lab, offers a solution for patients requiring full or partial dentures. Designed with state-of-the-art CAD/CAM technology, these dentures provide unparalleled fit, durability, and natural-looking esthetics. By utilizing digital workflows, dentists can streamline the denture fabrication process, ensuring consistent quality and predictable results.

COMPOSITION

PMMA

IN-LAB WORKING TIME

7-Days

WARRANTY

1 Year

conditional warranty

FLEXURAL STRENGTH

N/A

What are Ivoclar Digital Dentures?

Ivoclar Digital dentures are manufactured using precise milling techniques. These dentures achieve an exceptional fit, minimizing chairside adjustments. The final denture begins with a base or vestibular area milled in a tissue-colored material. Following this, the dental arch is milled in the selected tooth shade. The teeth are then securely bonded into the tissue-colored base. To ensure a precise fit, the joined pink and white materials undergo fine milling. The process is completed by polishing and refining the denture to achieve the finished product.

Burbank Dental Lab integrates Ivoclar’s digital denture workflow to deliver a more efficient, predictable, and high-quality solution for edentulous patients. The digital process eliminates traditional wax-ups and manual inconsistencies, providing a superior prosthesis that enhances both patient comfort and clinician convenience.

Key Features

REQUEST A QUOTE

Studies show that digital dentures outperform traditionally fabricated ones in terms of precision, retention, and patient satisfaction.

Indications for Use

Ivoclar Digital Dentures are suitable for:

REQUEST A QUOTE

Clinical Handling

Ivoclar Digital Denture Workflow

Record Collection

Taking Impressions

Vertical Dimension Measurement

Jaw Relation Record

Use scanned data to fabricate a 3D bite plate.

Bite Verification & Adjustments

Scanning & Initial Try-In

Final Denture Fabrication

REQUEST A QUOTE

Clinical Data

Studies show that digital dentures outperform traditionally fabricated ones in terms of precision, retention, and patient satisfaction. Research highlights the reduced number of adjustments needed post-insertion, demonstrating the advantages of CAD/CAM technology.

Additionally, the durability of Ivoclar’s PMMA materials ensures long-term success, minimizing fractures and wear over time.

REQUEST A QUOTE

FAQ

How do Ivoclar Digital Dentures compare to conventional dentures?

Ivoclar Digital Dentures offers improved fit, durability, and esthetics compared to conventional dentures. The digital design process minimizes errors, while the materials used provide superior strength and longevity.

What is the turnaround time for Ivoclar Digital Dentures?

On average, digital dentures can be fabricated in 7 working days. Expedited services may be available upon request.

Can digital impressions be used for Ivoclar Digital Dentures?

Yes, digital impressions provide an efficient and accurate method for designing Ivoclar Digital Dentures. However, high-quality traditional impressions are also accepted for cases where digital scanning is not an option.

REQUEST A QUOTE