The Revolution

The aesthetic revolution in dentistry began as pressed ceramics first became available nearly 30 years ago. With the launch of lucite reinforced IPS Empress® in the early ‘90s, the wide use of all-ceramic restorations became a reality. Initially pressed ceramics were only available as monolithic restorations and had limited indications for use. The restorations included were inlays and onlays, and single crowns 2nd bi to 2nd bi.

Within a few years, pioneers in the dental community began to explore options that would enable ceramics to be layered over the pressed substrate. Teaching institutions like The Las Vegas Institute (LVI) were formed to equip dental clinicians as well as technicians. Ivoclar collaborated with the early adopters in the dental community as they continued to develop and evolve the Ivoclar Porcelain Systems (IPS).

The next step forward was when IPS e.max®, lithium disilicate, was introduced 20 years ago. Even after 20 years, e.max is one of the most popular and versatile restorations. There have now been over 100 million e.max® restorations delivered. There is good reason for the popularity of e.max®. The data shows over 97% survival rate, and longitudinal evidence proves e.max to have a flexural strength of 500 MPa.

REQUEST YOUR FREE IMPLANT SUCCESS GUIDE BELOW

Success Guides

Advantages of e.max®

In addition to the outstanding strength that e.max® provides, it offers several other key features that make e.max® restorations uniquely beneficial for multiple restorative applications.

- Esthetics - natural esthetics are unequaled by any other monolithic restoration. e.max® also has tooth-like fluorescence, opalescence, and an enamel-like translucency.

- Precision marginal accuracy in both pressed and CAD/CAM milled restorations.

- e.max delivers wear rates that are almost identical to enamel.

- Ability to be layered. e.max® can be fabricated as a coping and fully layered, or micro layered strategically to add life-like esthetics where desired while the functional areas remain in monolithic material. e.max® delivers the best of both worlds - strength, and esthetics.

- Superior bond strength. e.max is an etchable ceramic, providing the ability to establish a very strong bond to the restoration using resin bonding systems. This superior bond strength makes the net system strength of an e.max® restoration comparable to restorations that have higher compressive strength.

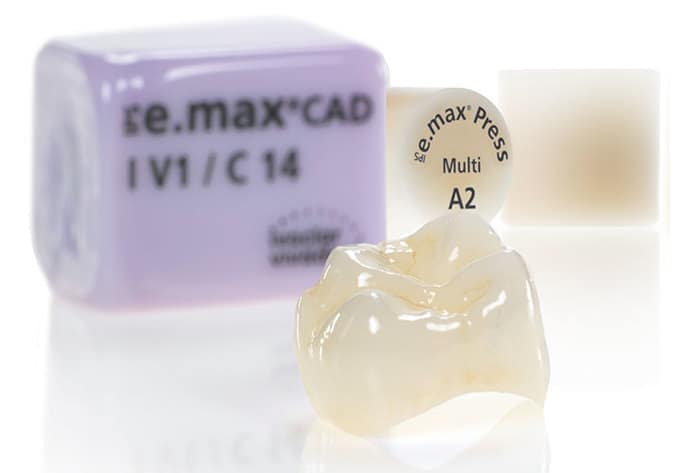

Variety of Ingots and Milling Blocks

The large variety of shades and opacity levels available in the Ivoclar e.max System allows for choices to be made to best accommodate the specific restoration requirements. (Figure 2 & 3) The following are the possible choices available:

Impulse ingots & blocks

- Value 1,2,3 ingots and blocks

- Opal 1 & 2 ingots and blocks

Impulse ingots are available in three brightness values (Value 1, 2, 3) and two opalescent shades (Opal 1, 2). They are mainly used to fabricate veneers, partial and single crowns with the same 500 MPa strength.

Multi ingots

These polychromatic and poly-translucent ingots provide a natural shade progression from the margin to the incisal edge and enable technicians to achieve a strong and highly esthetic restoration without needing to cut back and layer.

5 Levels of Opacity Ingots: HT, MT, LT, MO, HO Ingots & Blocks

HT ingots & blocks

The high translucency ingots (HT) are ideal for the fabrication of minimally invasive full-contour restorations, such as inlays, onlays, and veneers. The restorations can then be characterized with staining materials in the IPS e.max Ceram line.

MT ingots & block

The medium translucency ingots (MT) are perfect for a variety of indications from thin veneers to 3-unit bridges and are ideal for restorations requiring a higher brightness level than HT and more translucency than LT.

LT ingots & block

Full-contour partial crowns and crowns are fabricated beautifully with the low translucency ingots (LT). In the anterior region, in particular, the esthetic appearance of the restorations is maximized by employing the cut-back technique.

MO ingots & block

The medium opacity ingots (MO) are used to fabricate substructures for vital or slightly discolored teeth. They create an ideal basis for lifelike restorations completed with the layering technique.

HO ingots & block

In cases where the prepared tooth structure is discolored or titanium abutments are used, the HO ingots mask the dark background to achieve highly esthetic results.

Key Features:

- Strong - Flexural strength of 500 MPa

- Ideal for cosmetic cases, even in monolithic application e.max exhibits natural translucency that mimics enamel.

- Can be “micro” layered in cases where function requires extra strength of monolithic, but esthetic demands need to increase cosmetic results.

- No allergy potential or irritation of tissue.

- Low thermal conductivity provides greater comfort for your patient.

Indications for use:

- Crowns, and bridges up to 3 Units, with total lengths up to 14mm pontic span, or single crowns for all positions in the mouth.

- e.max can be layered or monolithic depending on the desired results

Contraindications:

- Not recommended for posterior bridges or anterior bridges over 14 mm pontic span.

Clinical Handling:

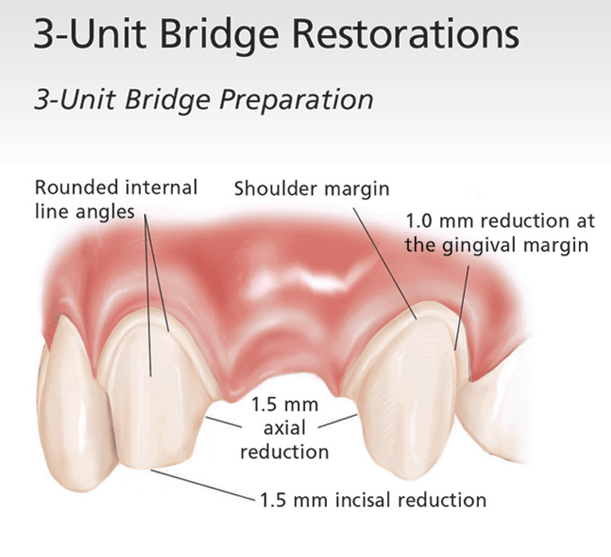

Preparation:

- 1mm shoulder or chamfer margin

- 1.5mm axial wall reduction

- 2mm incisal/occlusal reduction required.

- No Knife-edge margins

- Note: As with any all-ceramic, no sharp or right angles.

Cementation

e.max® can be bonded using adhesive systems with dual cure resins or cemented using low expansion cements, like resin-modified glass ionomers.

For greatest strength, and where preparation allows for a dry field (supra-gingiva margins), it is recommended to use adhesive bonding.

For restorations with subgingival margins, or when a dry field cannot be achieved, Ivoclar Vivadent recommends a hybrid glass ionomer cement system with less than 0.5 percent expansion.

Adjusting & Polishing

- When adjustments are necessary, adjust prepped tooth.

- Use a diamond with water for ceramic adjustments of veneer porcelain.

- Avoid carbide use.

In-Lab Turnaround Time – 7 Working Days

The Industry Standard

IPS e.max is the dental industry's standard for esthetic restorations that also deliver maximum strength. With over 30 years of longitudinal experience with this category of restoration, it is one of our most tested and reliable restorations.