Tooth loss remains a common challenge in clinical practice, whether due to caries, trauma, periodontal disease, or functional wear. Beyond esthetics and implant technology, missing teeth can compromise function, nutrition, and long-term oral health. Dental implants remain one of the most reliable and predictable solutions for restoring both form and function.

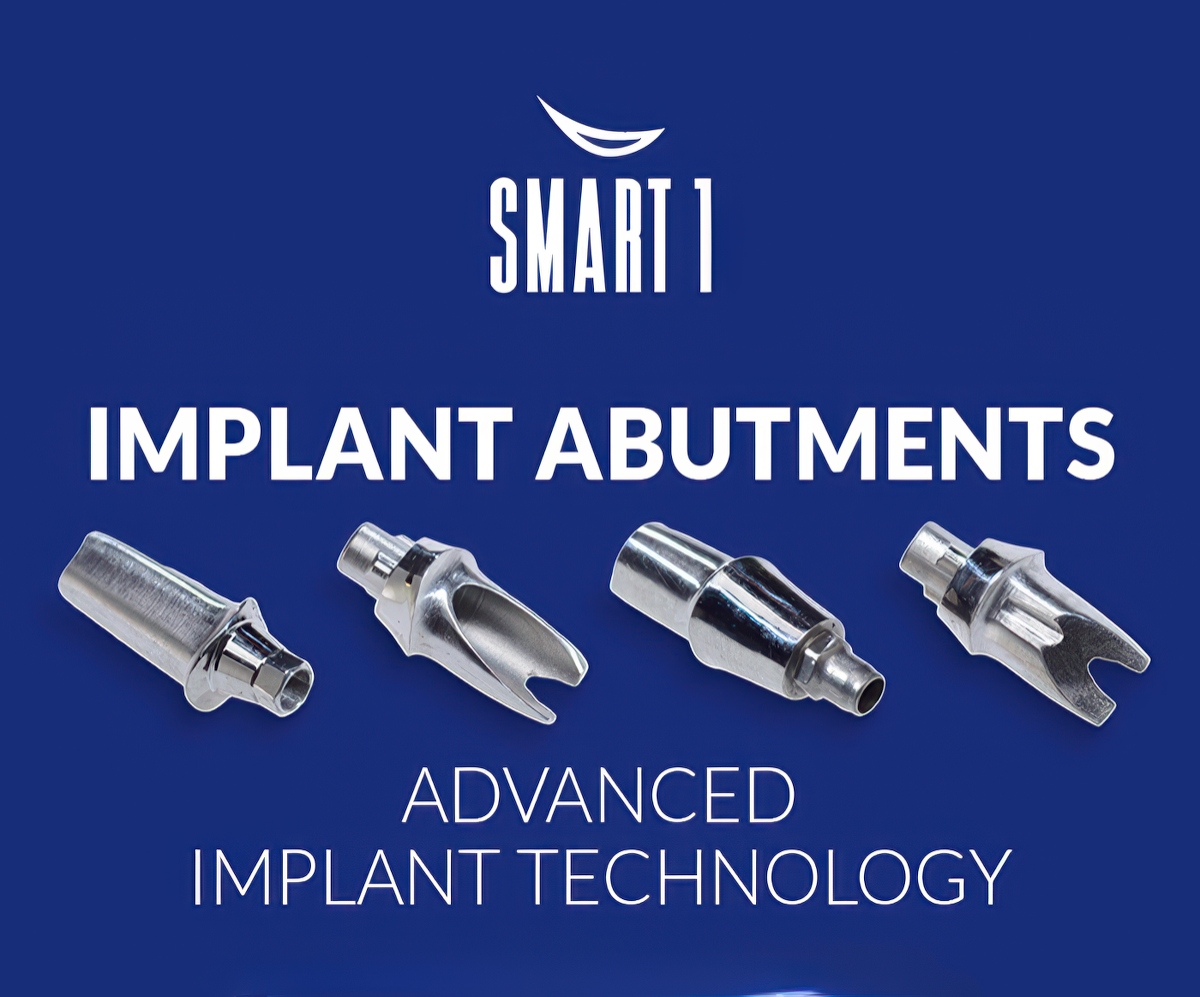

According to data summarized by the American College of Prosthodontists, approximately 2.3 million implant-supported crowns are fabricated each year in the United States. With demand at this scale, the performance of the abutment you choose directly affects soft-tissue stability, restorative success, and long-term maintenance. That commitment to predictability is what led Burbank Dental Lab to develop the SMART 1 Implant Abutment, a fully customized abutment system engineered to support precision, esthetics, biologic health, and advanced implant technology.

SMART 1 Manufacturing: Designed Around Clinical Needs

Every SMART 1 abutment begins with the needs of the case, not a stock library. The design process focuses on creating an ideal emergence profile that supports tissue maturation, maintains biologic width, and delivers consistent esthetics. Customization also allows for correction of implant angulation and more precise restorative support.

Burbank Dental Lab manages the abutment workflow from design through production, using a complete digital environment to maintain control over shape, fit, and accuracy. One key differentiator is the use of in-house computer-numerically controlled (CNC) milling, a capability found in fewer than 5% of U.S. dental laboratories. CNC milling enables extremely accurate interfaces and reproducible machining, which supports better seating, reduced complications, and long-term restorative stability.

Clinical advantages include:

Material Selection: Matching the Abutment to the Case

Material selection is central to esthetic and functional outcomes, particularly in thin biotypes or high-visibility regions. SMART 1 abutments are available in titanium, zirconia, and hybrid configurations to meet a range of clinical requirements:

Hybrid designs that pair zirconia with a titanium base combine the strength and precision of metal with the esthetic advantages of zirconia coronally.

FREE TO DOWNLOAD – SUCCESS GUIDES

DOWNLOAD A GUIDE

Cement-Retained SMART 1 Abutments

Cement-retained abutments remain an excellent choice when screw access would compromise occlusal or esthetic integrity. SMART 1 cement-retained abutments are available in titanium or zirconia with a titanium base and are suitable for both single-unit and multi-unit restorations.

Clinical guidelines:

Screw-Retained SMART 1 Abutments

Screw-retained restorations support retrievability and reduce risks associated with excess cement. Ideal screw access positioning can be achieved through guided surgical approaches, improving both function and esthetics.

SMART 1 offers two primary screw-retained options:

CO/CR abutments:

Zirconia abutments with a titanium base:

Indications for screw-retained options:

Advanced Clinical Protocols with SMART 1 Abutments

SMART 1 implant abutments were designed for both precise restorations and to support advanced clinical workflows that enhance predictability and reduce treatment times. As implant dentistry increasingly embraces digital techniques, minimally invasive practices, and biologically guided protocols, SMART 1 offers a foundation that integrates smoothly with advanced treatment planning and delivery methods.

Digital planning and guided workflows

SMART 1 abutments are fully compatible with digital implant planning systems, enabling clinicians to achieve optimal implant positioning and screw-access trajectory. When combined with guided surgery, SMART 1 supports:

This collaboration enables clinicians to uphold a restorative-driven approach to implant placement, which is especially beneficial in the esthetic zone and in multi-unit cases.

Immediate provisionalization protocols

For cases selected for immediate temporization, SMART 1 implant abutments offer controlled emergence and precise margins that maintain tissue stability during healing. The custom subgingival contour prevents soft-tissue collapse and preserves papilla architecture, improving the transition from provisional to final restoration. This protocol is especially effective in:

Soft-tissue development through provisionalization

SMART 1 implant abutments support sculpting of peri-implant tissues through provisional restorations. Clinicians can achieve a predictable papilla height and a gingival scallop by adjusting provisional contours without compromising the abutment. This biologically driven approach enhances long-term esthetic success by ensuring:

Complex angulation and multi-unit rehabilitation

In full-arch or multi-unit cases, angulation discrepancies can compromise screw access, occlusion, or esthetics. The custom design of SMART 1 enables tailored solutions that address specific conditions, such as:

This level of customization significantly reduces the need for compromise restorations in complex prosthetic treatments.

Enhanced biologic health through customized margins

The margin placement for SMART 1 adheres to the biologic width and promotes long-term health around implants. Clinical protocols that benefit from customized margin control include:

By placing margins exactly where biology allows, SMART 1 reduces the risk of inflammation and improves long-term predictability.

For clinicians, the abutment serves as a crucial link between surgical placement and successful restoration. SMART 1 Implant Abutments integrate precise digital design, CNC-level manufacturing, and careful material selection to ensure reliable outcomes across a wide array of implant indications. Whether you are restoring a posterior molar, handling an esthetic-zone single unit, or planning for immediate temporization, SMART 1 provides a customized solution that supports long-term function, aesthetics, and biological preservation.