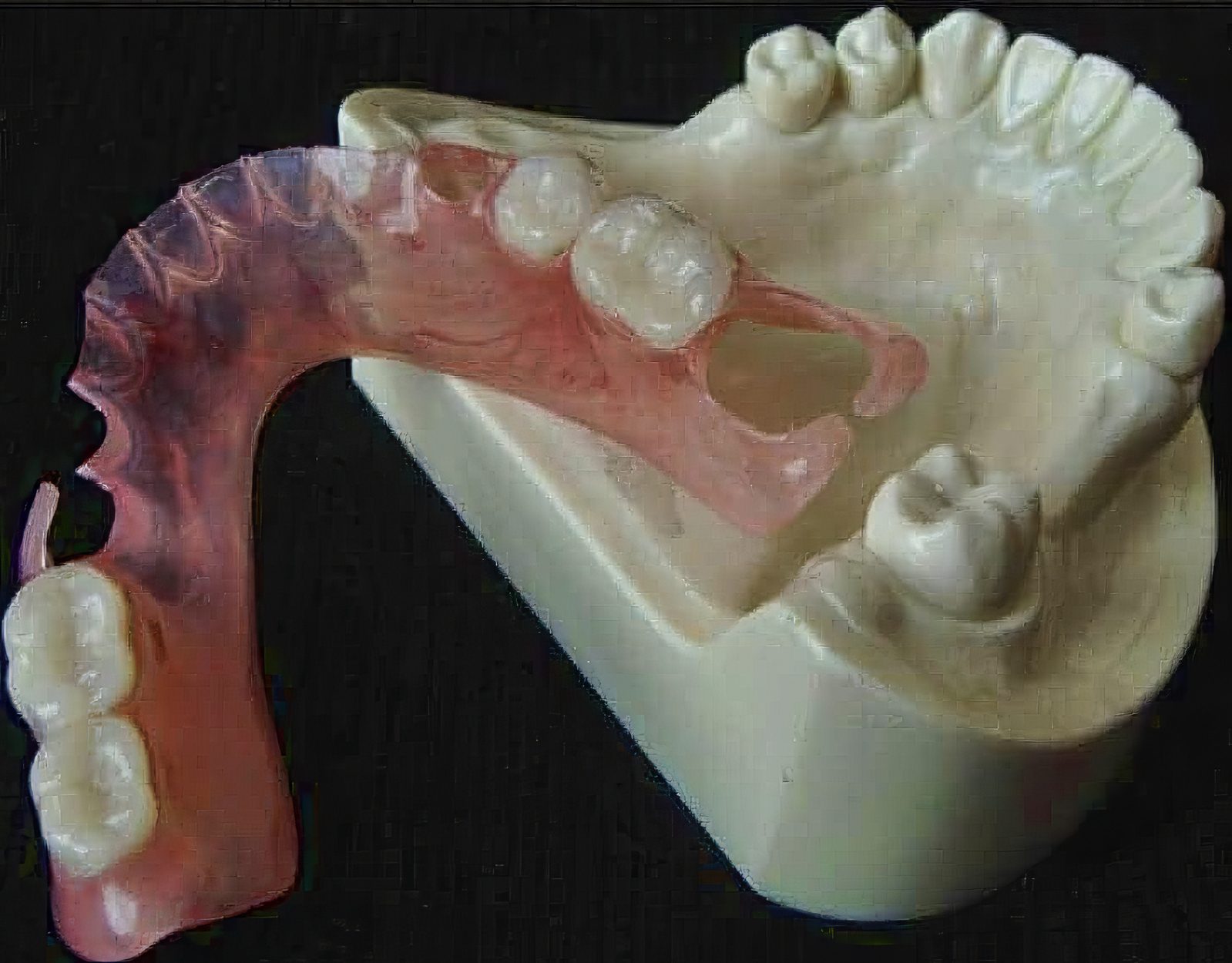

Flexible partial dentures, including Valplast® and other nylon-based thermoplastic materials, are routinely delivered from the dental lab fully finished and polished. However, dentists may need to perform chairside adjustments and polishing to relieve sore spots, smooth borders, or refine clasp areas during delivery or follow-up visits.

Because flexible partials are made from nylon thermoplastic rather than acrylic, they require a specific clinical approach. Using incorrect burs, excessive speed, or acrylic polishing techniques can damage the surface or distort the appliance. This guide outlines a clinically appropriate, chairside-only protocol for safely and effectively polishing flexible partial dentures.

What materials are used to make flexible partial dentures?

Flexible partial dentures, including Valplast® and similar systems, are fabricated from nylon-based thermoplastic materials, not acrylic resin. In the clinical setting, this generally means:

Understanding these material characteristics is essential before performing any chairside adjustment or polishing.

When is chairside polishing of flexible partial dentures appropriate?

Chairside polishing of flexible partial dentures is commonly performed when addressing:

When an appliance needs major reshaping, recontouring, or cosmetic refinishing, it is generally best to return it to the dental lab.

What tools are commonly used to polish flexible partial dentures chairside?

Dentists typically select tools designed for thermoplastic materials when adjusting or polishing flexible partial dentures.

Chairside-appropriate tool categories

Specific instrument selection and operating parameters may vary by manufacturer and clinician preference. These tools are often sold as kits.

FREE TO DOWNLOAD – SUCCESS GUIDES

DOWNLOAD A GUIDE

How do dentists polish flexible partial dentures chairside?

Step 1: Identify the area requiring adjustment

Pressure-indicating paste, disclosing wax, or patient feedback may be used to localize the area contributing to irritation. Clinically, adjustment is generally limited to the minimum amount of material necessary to relieve the issue.

Step 2: Perform minimal reduction (If indicated)

When material removal is indicated:

The clinical objective is localized relief rather than reshaping the appliance.

Step 3: Smooth the adjusted surface

Following reduction, the adjusted area may appear dull or irregular.

At this stage, the surface is evaluated primarily by tactile smoothness rather than appearance.

Step 4: Chairside polishing for patient comfort

In most clinical situations, achieving a smooth satin finish is considered sufficient for patient comfort.

A high-gloss cosmetic finish is not usually required to achieve comfort.

Can flexible partial dentures be polished to a higher shine chairside?

In some cases, a limited increase in surface luster may be desired.

This step is optional and is generally approached conservatively.

Chairside polishing of flexible partial dentures, such as Valplast®, is safe and effective when performed with the appropriate tools and expectations. By using thermoplastic-compatible burs, silicone- or rubber-polishing techniques, and a conservative approach, dentists can quickly restore patient comfort without compromising the appliance.

Contact Burbank Dental Lab today to get started on your next partial denture case.

FAQ