Cavities, trauma, genetics, and periodontitis are major contributors to tooth loss. Dental implants have been a successful treatment modality for well over 30 years. Before implants, bridges and dentures were the standard treatment option. However, implants offer predictability and a high success rate.

One of the key factors to the success of this treatment begins with implant surgery. One of the critical questions that must be answered when treatment planning is whether to implement freehand techniques or guided surgery.

There are many considerations as to which approach to employ, and this decision is made by factoring in the circumstances of each case and the clinician’s inclination. Freehand techniques are a more cost-effective approach that utilizes diagnostic information to place the implant.

In comparison, guided surgery uses a digitally designed surgical guide that offers a high level of accuracy and predictability.

Guided Surgery

The freehand technique is successful and is used to place many implants; however, a high level of precision is reached when guided surgery methods are used. Guided surgery helps implant placement go much faster. The more quickly an implant can be placed, the less time the flap needs to be open, which reduces the patient’s discomfort.

In addition, the efficiency gained through this method helps the profitability of the clinician. Surgical guides reduce stress, improve consistency, and allow the implant to be placed precisely according to the treatment plan.

Guided surgery cases require a cone-beam computed tomography scan (CBCT) and a digital impression. These are used to create an accurate virtual likeness of the oral anatomy.

With this data, a digital treatment plan is created, which provides the best possible positioning of the implant. A surgical guide is fabricated that will control the implant surgery as detailed from the digital plan. Every aspect from the angulation, depth, and location is set and recorded within the surgical guide.

The overall workflow in this process is as follows:

1. CBCT scan

A CBCT scan is needed and must be exported using a RAW DICOM file format. This file format is necessary to open in the Blue Sky plan software.

2. STL file

STL File is needed and can be obtained with the following methods:

- Intraoral Scan

- CT scan of a model

- CT scan of a polyvinyl siloxane impression

- Desktop scanner

3. Open-guided implant planning software

Information is sent to one of many open guided implant planning softwares. Here the data is analyzed to determine where the implant should be placed.

Considerations are made concerning bone volume, nerves, sinus, and adjacent tooth positions.

When there is limited space, the guided plan situates the implant in the best possible location.

4. Implant placement

It is recommended that the implants are placed using a prosthetically-driven treatment plan. The key is to try and place the implant in the central groove as much as possible.

5. Fabrication

The proposed plan is sent to Burbank Dental Lab to fabricate an accurate surgical guide complete with drill stops.

In addition to the accuracy that guided surgery provides, final esthetics is also greatly improved with this method. Through digital treatment planning, one can start with the end result in mind and create the ideal implant solution to fit the desired result.

Because guided surgery cases offer unmatched precision, the implants can be placed in ideal positions creating the best esthetic outcomes.

Guided Surgery Blue Sky – Case Study

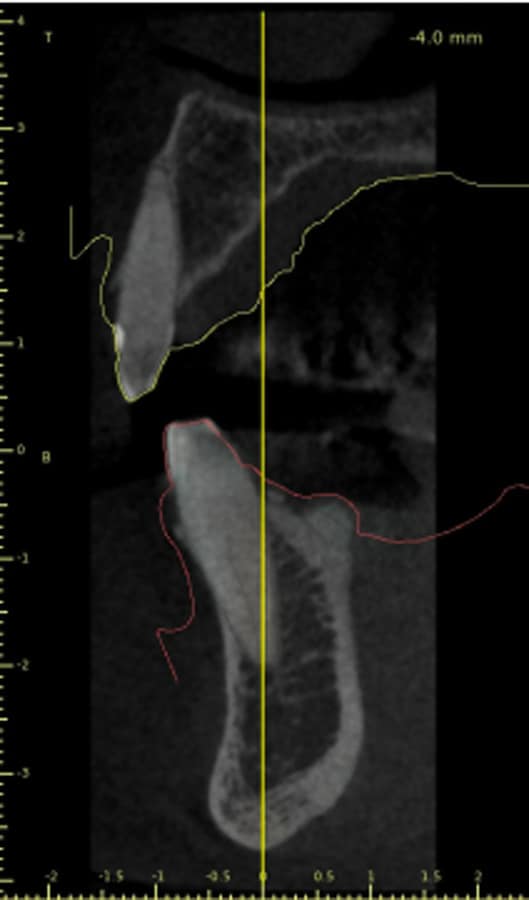

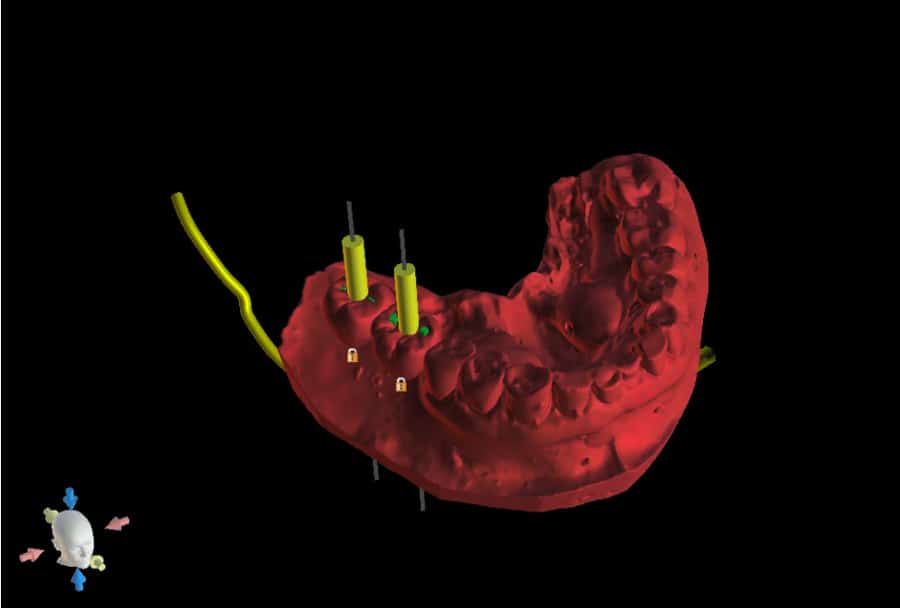

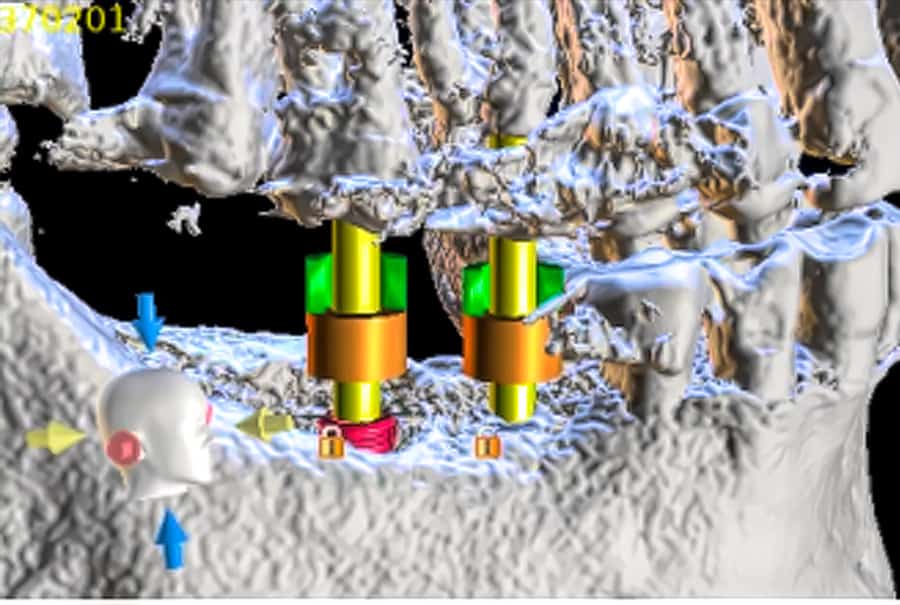

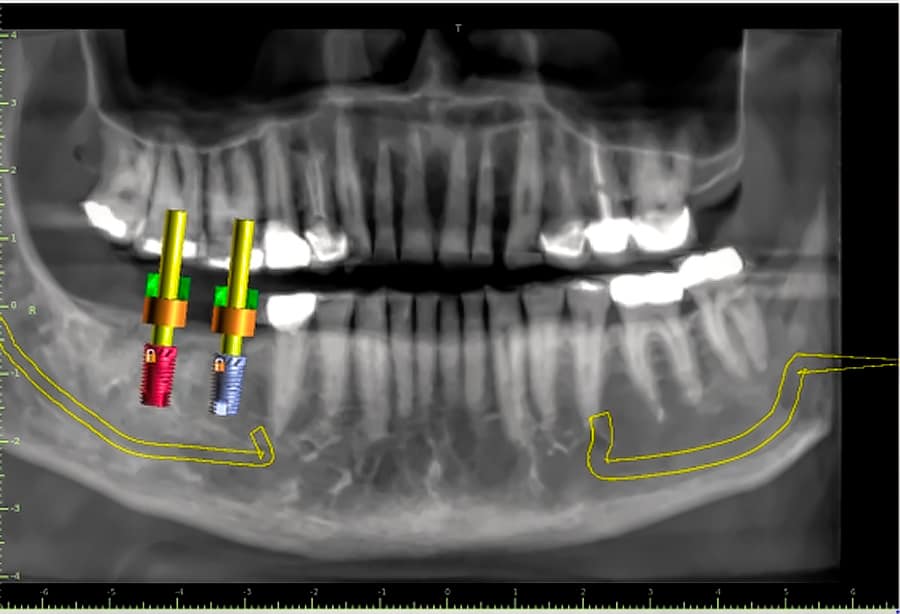

This patient presented in need of implants for teeth numbers 30 and 31. A CBCT scan and intraoral scan were done and sent to Blue Sky Plan software, where they were carefully stitched together (Figure 1, shown below).

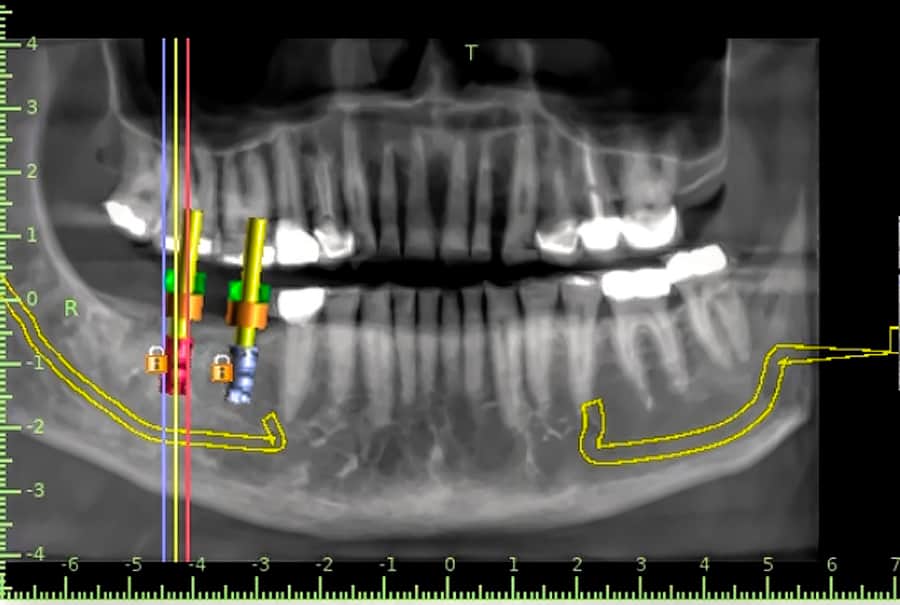

From this data, the proposed implant placement is made (Figure 2, shown below).

Cases with the best results are those that are prosthetically driven. Understanding where the final crown will be placed is critical to case success.

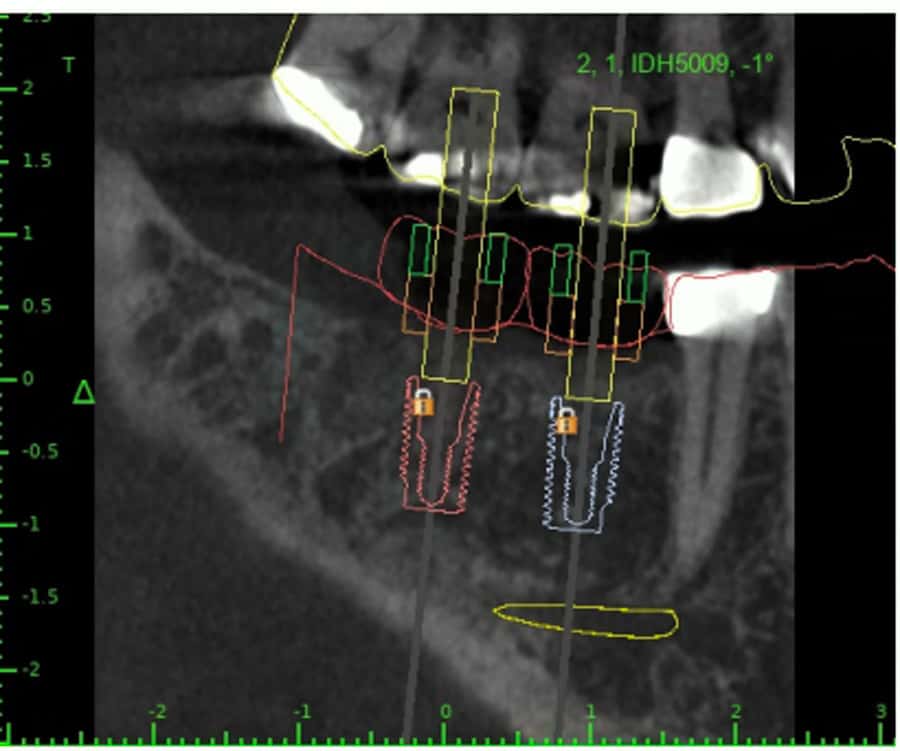

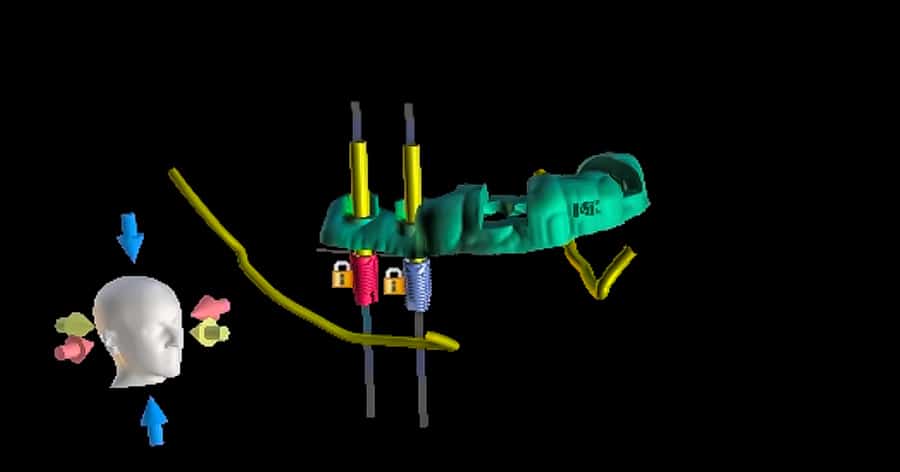

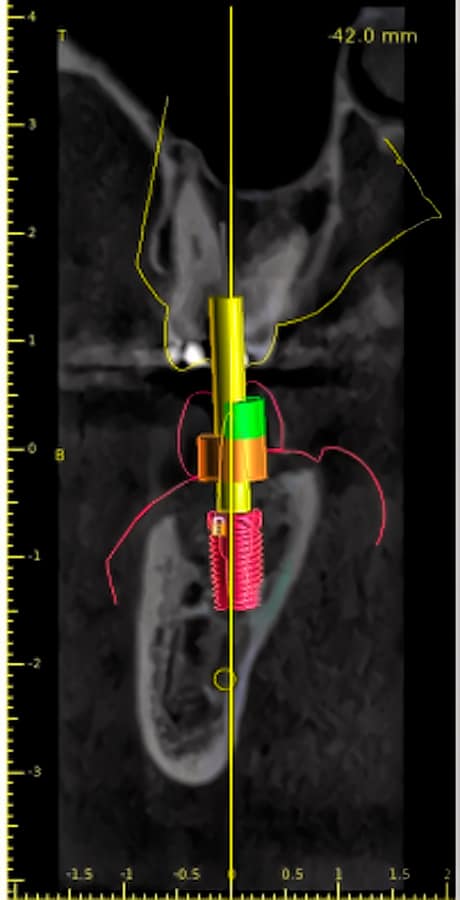

In this case, waxed-up crowns were used, and the proposed implant placement is designed with the emergence coming through the central fossa. This is marked with yellow abutment cylinders (Figure 3, shown below).

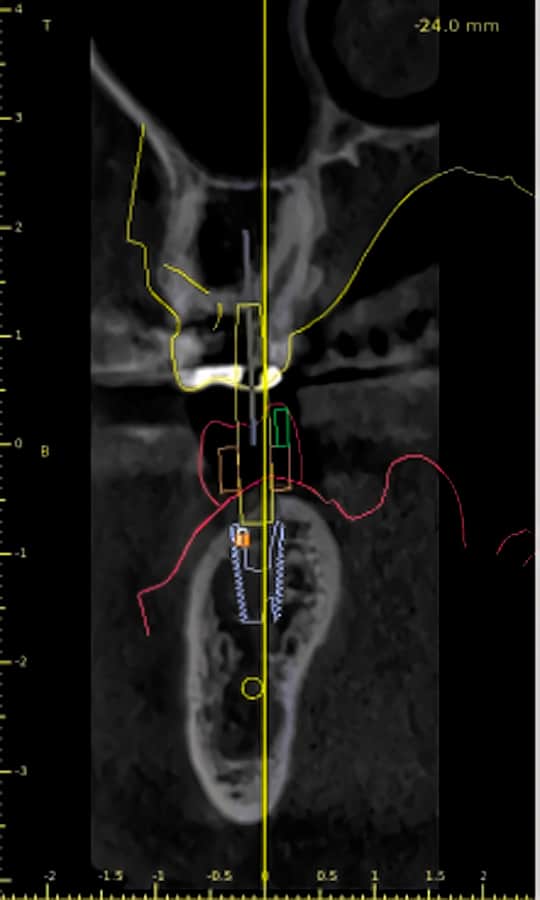

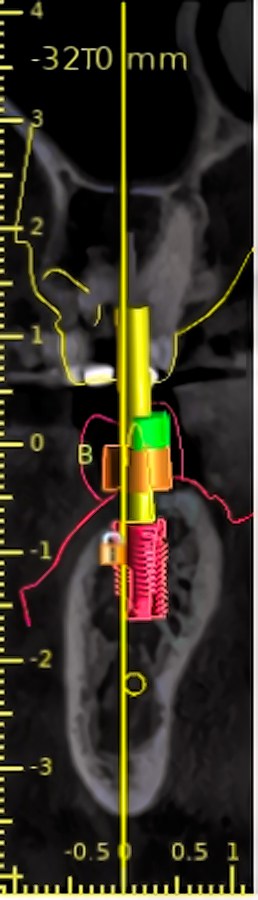

Next, the implants were designed to be below the functional max cusps (Figure 4, shown below).

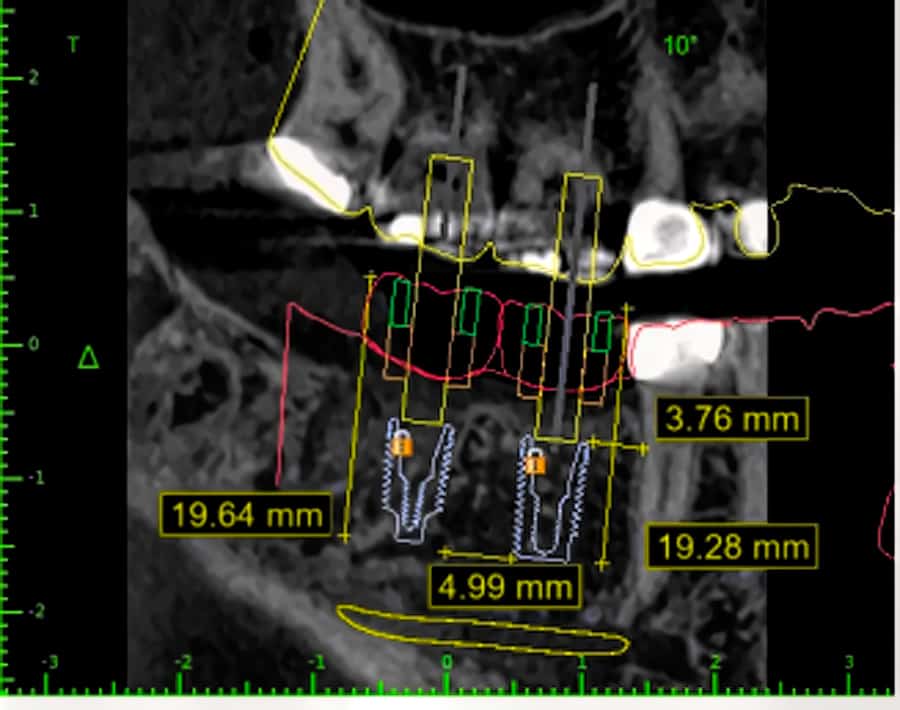

It is crucial to consider the space and position of adjacent teeth and the space between the implants.

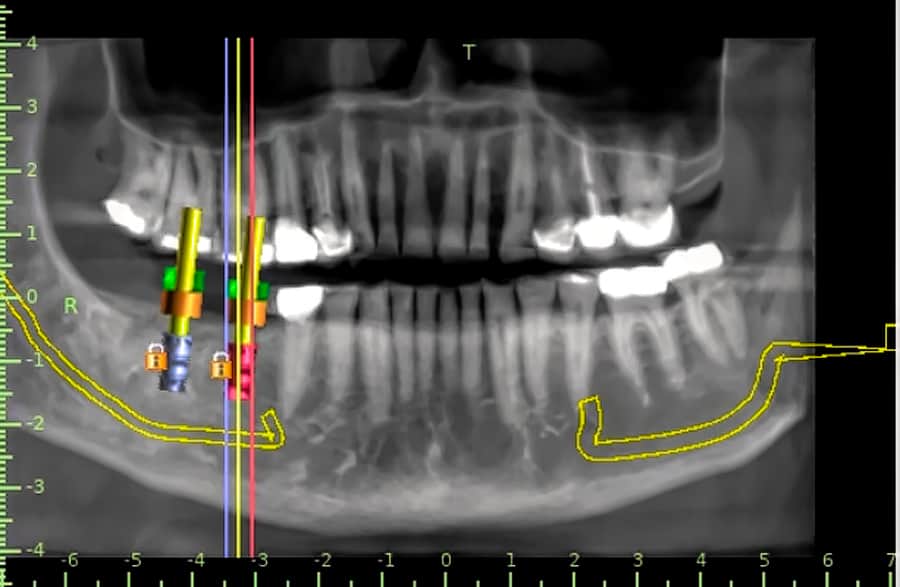

Figure 5, shown below shows the distances from the distal of #29 and the space between #30 and #31. This aspect also provides the depth measurements for drilling.

The proposed implants are also evaluated regarding their proximity to nerves (Figure 6, shown below) and their relation to the bony crest (Figure 7, shown below).

This data can then be used to begin the virtual constructing of the surgical guide. The metal cylinders used in the surgery guides are unique to the type of surgical system used.

The guide for this case includes drill stops and guide tubes manufactured by Blue Sky Bio (Figure 8, shown below).

Final checks were made of #30 and #31.

The software provided a view of #30, showing the edge to be even with the buccal bone and the apical implant just above the lingual plate of the cortical bone (Figures 9 and 10).

For number 31, the 3D view shows a buccal deficiency that will need to be filled with bone from surgery or bone graft material. (Figures 11 and 12)

Guided Surgery Appliance

Once the treatment plan is finalized, the fabrication of the guided surgery appliance is essential to the osteotomy’s accuracy. The finalized data can be sent to Burbank Dental Lab, where guided surgery appliances are created.

Burbank Dental Lab offers solutions to several different workflows. The guides are fabricated on digital printers with titanium guide cylinders that match the surgical system in use by utilizing advanced manufacturing methods.

It is important to note that Burbank Dental Lab’s surgery guide manufacturing capabilities are compatible with all software systems as long as they can export an STL file.

The benefits of surgery guides manufactured by Burbank Dental Lab:

- Turnaround times are just two working days.

- The guides are manufactured with FDA-approved printed resin.

- The guide rings are unique to the surgical system being used.

- All guides are tried on a solid model to verify fit.

While freehand implant placement is possible and is quite successful, implants placed with a guided surgery method offer improved diagnostics, accuracy, a treatment plan, and overall improved patient experience and case outcome. It also improves implant placement times and is more efficient.

Connect with us via chat below or give us a call at (800) 336-3053. A Burbank Dental Lab implant team specialist is ready to assist you with your next guided surgery appliance.