Technology has brought many advances to computer-aided design and manufacturing (CAD/CAM) in many industries. For example, in dentistry, the evolution of CAD/CAM has led to improved accuracy in the fabrication of fixed prostheses. However, removable denture prosthetic manufacturing has been slow to switch over to digital manufacturing techniques.

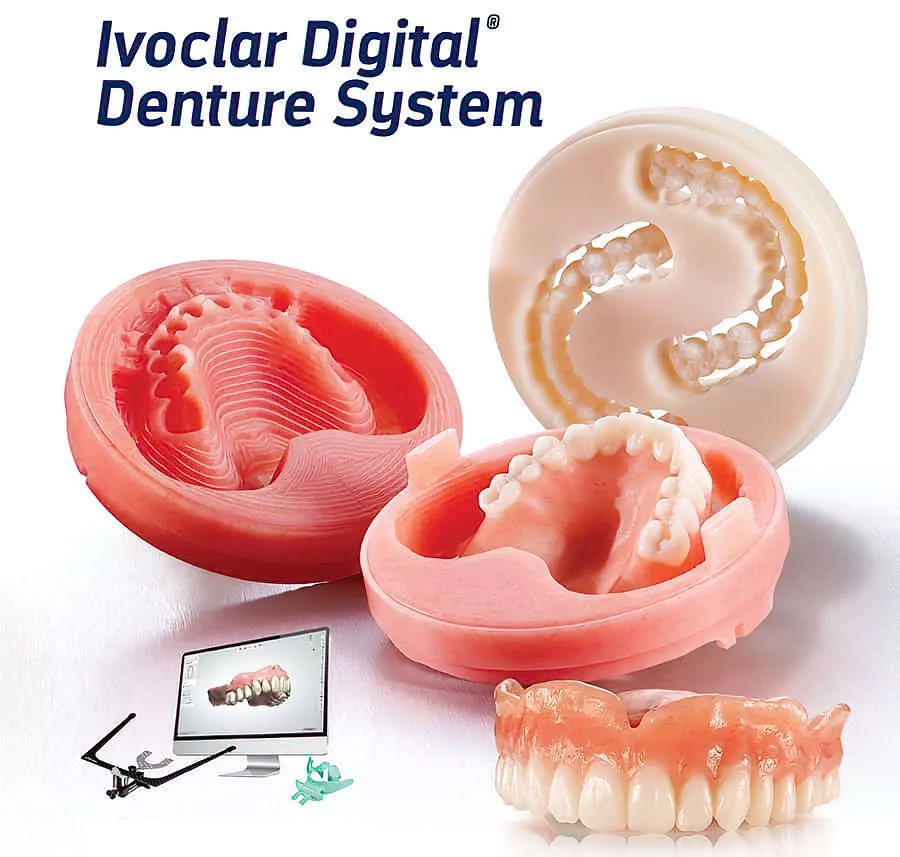

Traditional denture workflows are labor-intensive. When issues arise due to inaccuracies with the vertical dimension of occlusion or even esthetics, it is a laborious process to reset the denture. With digital workflows, corrections such as these can take as little as fifteen minutes to perform. One of the newest digital denture workflows we have implemented at Burbank Dental Lab is the Ivoclar Digital Denture system.

Digital Denture Process

With the advantage of being one of the first dental labs to incorporate the Ivoclar Digital Denture process, Burbank Dental Lab has created systems that integrate this technology to develop successful case outcomes.

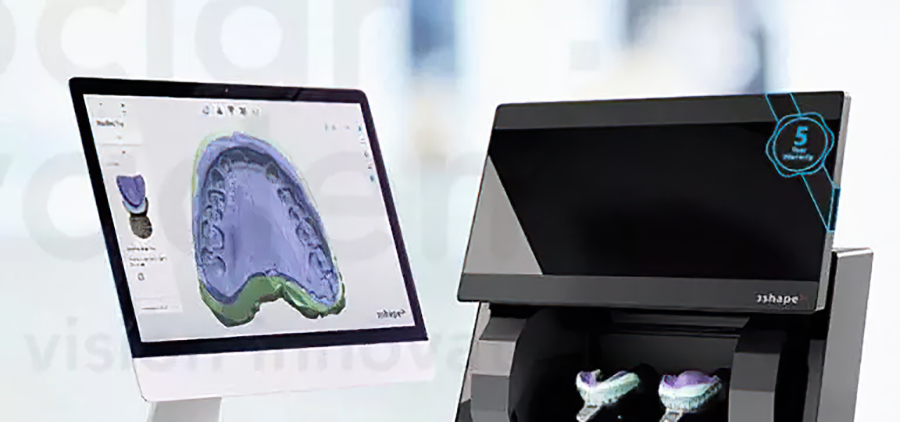

A digital denture workflow requires the data recording steps done in the dental office and the digital design and manufacturing processes done in the dental lab. The records provided by clinicians are crucial to ensuring accuracy. In addition, the lab must stay current on the latest software, materials, and production strategies to deliver consistent results.

Benefits of Ivoclar’s Digital Dentures

The main challenge experienced when working with traditional denture workflows is the labor-intensive time consumption this method poses. In addition, when there is a discrepancy with a traditional denture, such as issues with aesthetics, inaccuracies with occlusion, or the midline being off, the complete process needs to be restarted.

Traditional dentures are very time-consuming. However, a digital workflow allows for quick and easy corrections as only the digital inputs need to be altered.

In addition, digital denture processes provide the following benefits:

REQUEST THE BURBANK DENTAL LAB FEE SCHEDULE

REQUEST FEE SCHEDULE HERE

REQUEST FEE SCHEDULE

Digital Denture Workflow – Ivoclar

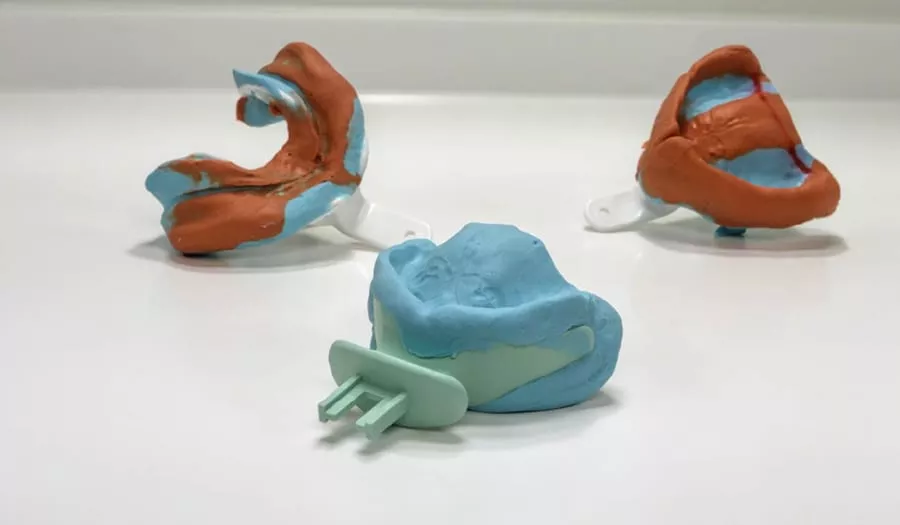

1. Record the bite and impressions

The first step will be to record the bite and impressions. You can do this either digitally or with conventional methods. In most cases, these records are recommended using conventional methods.

The following records are needed:

- Anatomical impression

- Border mold impression

- Mark the dorsal margin and reinsert

2. Document the vertical

- You should place a dot on the patient’s chin and nose. Then measure the dots and record the distance.

- Use a centric tray to record the jaw by having the patient close to the vertical dimension of occlusion that was marked previously.

3. A UTS CAD is used to register and measure the angle of the occlusal plane.

A UTS CAD is now used to register and measure the angle of the occlusal plane as it relates to the Camper’s plane and the bipupillary line.

This measurement is transferred to establish the correct position of the occlusal plane to be used in the virtual denture design. This is how the digital models are oriented to create 3-D bite plates.

4. Manufacture a 3-D bite plate

The digital information is used to manufacture a 3-D bite plate.

5. Verification

- Check the fit

- Ensure the bite is level

- Analyze the final occlusal plane

6. Record

Record final impressions.

7. Import scans

Import scans into the digital denture software.

8. A monolithic denture is printed.

A monolithic denture is printed using the data gathered from the previous steps.

The following is checked for accuracy:

- Smile line

- Midline

- Lip support

- Buccal corridor

- Position of the incisal edge

- Verify occlusion and make any needed adjustments

- Check the patient for any speech issues.

Once all data is gathered and verified, the final denture can be fabricated.

FREE TO DOWNLOAD – SUCCESS GUIDES

DOWNLOAD A GUIDE

Final Denture Fabrication

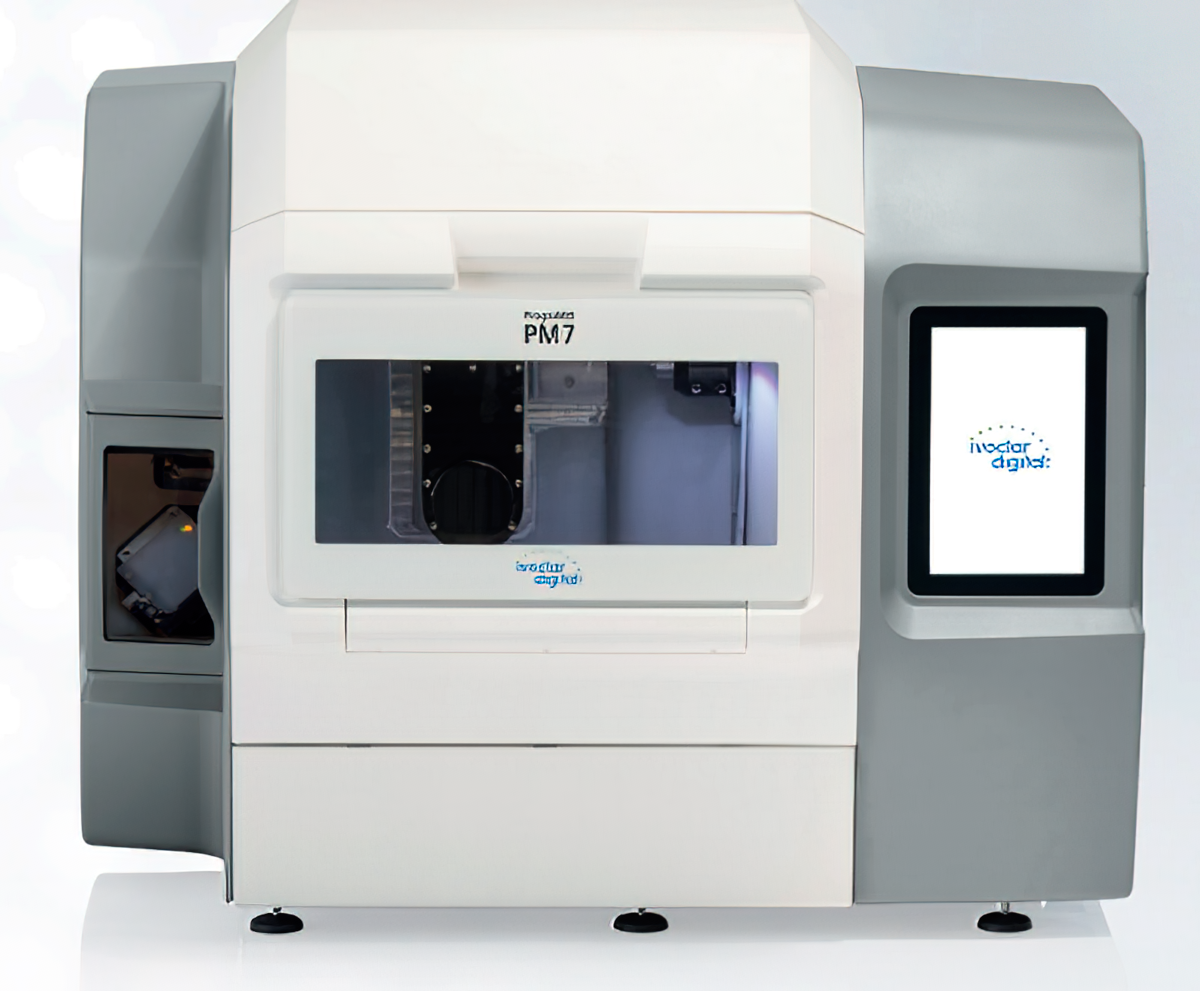

The final denture is then milled using a high-powered milling machine that produces exceptionally high-precision dentures. The process uses a tissue-colored denture base. The chosen tooth color shade is used to select the right material to mill the dental arch. The teeth are then cured into the pink tissue material.

A final fine milling process is completed to bond both the white and pink material together.

The material used to mill the denture is more durable than traditional denture materials and stain and odor resistant.

A final finishing and polishing, then complete the denture. The result is a denture with more retention ensuring the patient will experience fewer sore areas. In addition, the fit is so good that there have been instances where cases have been fabricated without a post-palatal seal.

Digitally designed and milled dentures provide a unique workflow that streamlines the process of complete denture manufacturing. The digital denture process offers a way for clinicians to improve the denture process for their patients. The process is more predictable, easier to adjust, and provides a more pleasant experience for everyone involved. Being one of the first dental labs to incorporate Ivoclar’s Digital Denture System helped Burbank Dental Lab fully integrate and understand what is needed for success with these types of cases.

Contact the removable team at Burbank Dental Lab to discover how digital denture workflows can help you with your next removable case.