Implant rehabilitation processes continue to expand and evolve to meet the challenges of modern dentistry. Patients’ needs often are the driving force behind these changes as patients demand higher esthetic outcomes, pain-free experiences, and shorter treatment times. Implant immediate loading is an implant protocol that has evolved due to the increase in patient expectations.

Benefits of Implant Immediate Loading

Implants, in general, can take anywhere from three months to twelve months to complete the treatment, depending on the specific indication. For the patient, this can mean several trips to the dentist. Through immediate implant placement and immediate implant loading, the time commitment is significantly reduced.

Other benefits of implant immediate loading include:

FREE TO DOWNLOAD – SUCCESS GUIDES

DOWNLOAD A GUIDE

Patient Evaluation

For implant immediate loading to be successful, careful patient selection is crucial. Implant stability is the most important factor in reaching clinical success. Therefore, to move forward with this type of placement, it is essential to evaluate the bone quantity and quality.

A Computerized Tomography (CT) scan is one of the best ways to evaluate bone density and determine the viability of the proposed treatment.

Other criteria when evaluating a good candidate for implant immediate loading include:

Case selection is critical to avoid failures, and discussing the issues that could arise with patients should be done to mitigate any potential failures or esthetic challenges.

Clinical Case

Burbank Dental Lab was fortunate to work with Dr. Daniel Domingue on the following implant case. The patient presented with an unsavable upper lateral. She was leaving town and needed to leave with a tooth. After examination, it was determined that she was a good candidate for immediate implant placement.

The patient was sedated, and the tooth was extracted (see above image). An immediate implant was placed.

The implant used was a 3.5 x 13 MegaGen Anyridge implant.

An immediate temporary was placed on a PEEK abutment. The patient was able to leave town with a functioning temporary in place.

Digital Workflow

This case was scanned using a digital scanner (3Shape). Digital impressions create improved workflows in single-unit implant cases.

This patient needed to have the final abutment and crown finished in 7 days. Digital workflows help to improve turnaround times and provide this patient with the timeline she required. In addition, intraoral scanners also provide the following benefits:

The implant was given time to integrate. The patient returned after three months for the final restoration. The patient was scanned using a scan body to capture the specific implant information. In addition to the scan body, an opposing and bite record are also recorded. The data was viewed as a 3-dimensional model on a screen. The scan was evaluated to ensure the necessary information was captured.

The digital file was uploaded to Burbank Dental Lab. In addition, detailed information such as implant information, desired abutment specifications, esthetic concerns, crown material, and any other information could be provided to ensure the case is successful at the seat appointment.

A Burbank Dental Lab implant team member can assist with the steps above or answer any questions to ensure a successful outcome.

Design and Manufacture

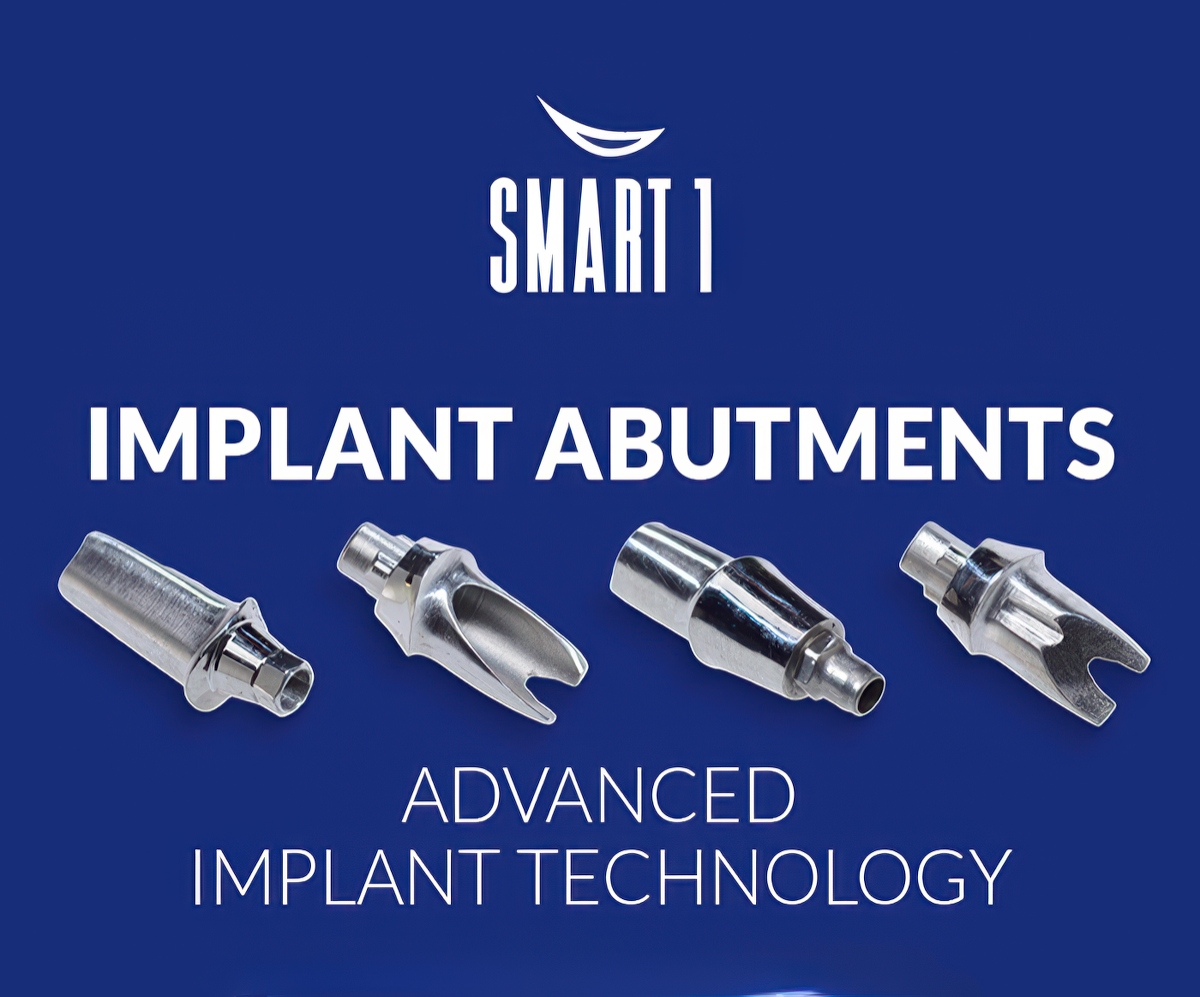

Burbank Dental Lab received the digital files and began the process of design. The files were evaluated to ensure no issues were present. A SMART 1 Zirconia Abutment was designed and milled with a layered zirconia crown to match the surrounding dentition.

Accuracy in these types of cases relies on the precision of the equipment being used to both design and mill the final output. At Burbank Dental Lab, the milling is done using CNC (computer numerical control) milling machines that produce a high level of accuracy. This is crucial in the customization of not only margins and contacts for crowns but also crucial for customized implant abutments.

SMART 1 Abutments

Once the abutment was designed and milled, the final restoration was then completed (fig 3). It was determined that a layered ZIRMAX Zirconia crown would be necessary to blend and match the surrounding dentition. Once completed, the case was sent to Dr. Daniel J. Domingue for insertion.

Use the following protocol when delivering SMART 1 zirconia abutments:

This restoration option created an excellent result that was natural and met the patient’s esthetic concerns (see above image). The implant immediate load protocol was a perfect treatment option for this patient as it met her timing demands as well.

Being able to offer a solution for patients who travel a lot and need an option when it comes to implant treatments is invaluable. This patient had her needs met and left the appointment a fan.

The dental industry, in general, has seen huge improvements and changes to workflows with procedures such as implant therapy. These changes are often patient-driven. With immediate load implant procedures, patients can experience a more efficient method of replacing missing dentitions. These cases address time issues, travel issues, esthetic issues, and issues with discomfort.

Call or chat today to get started on your next implant case.