Implant-supported restorations have emerged as the leading treatment method in dentistry, particularly for treating edentulous patients. These restorations serve to rehabilitate oral function and support the maintenance of healthy bone and soft tissues, delivering aesthetically pleasing and comfortable solutions for patients.

At Burbank Dental Lab, we are dedicated to advancing this field with the innovative SmartComposite Hybrid, a distinctive material specifically designed for fixed dental restorations.

Here’s why the SmartComposite Hybrid stands out:

The SmartComposite Hybrid, with its distinct attributes, sets a new standard in fixed dental restorations.

What is The SmartComposite Hybrid?

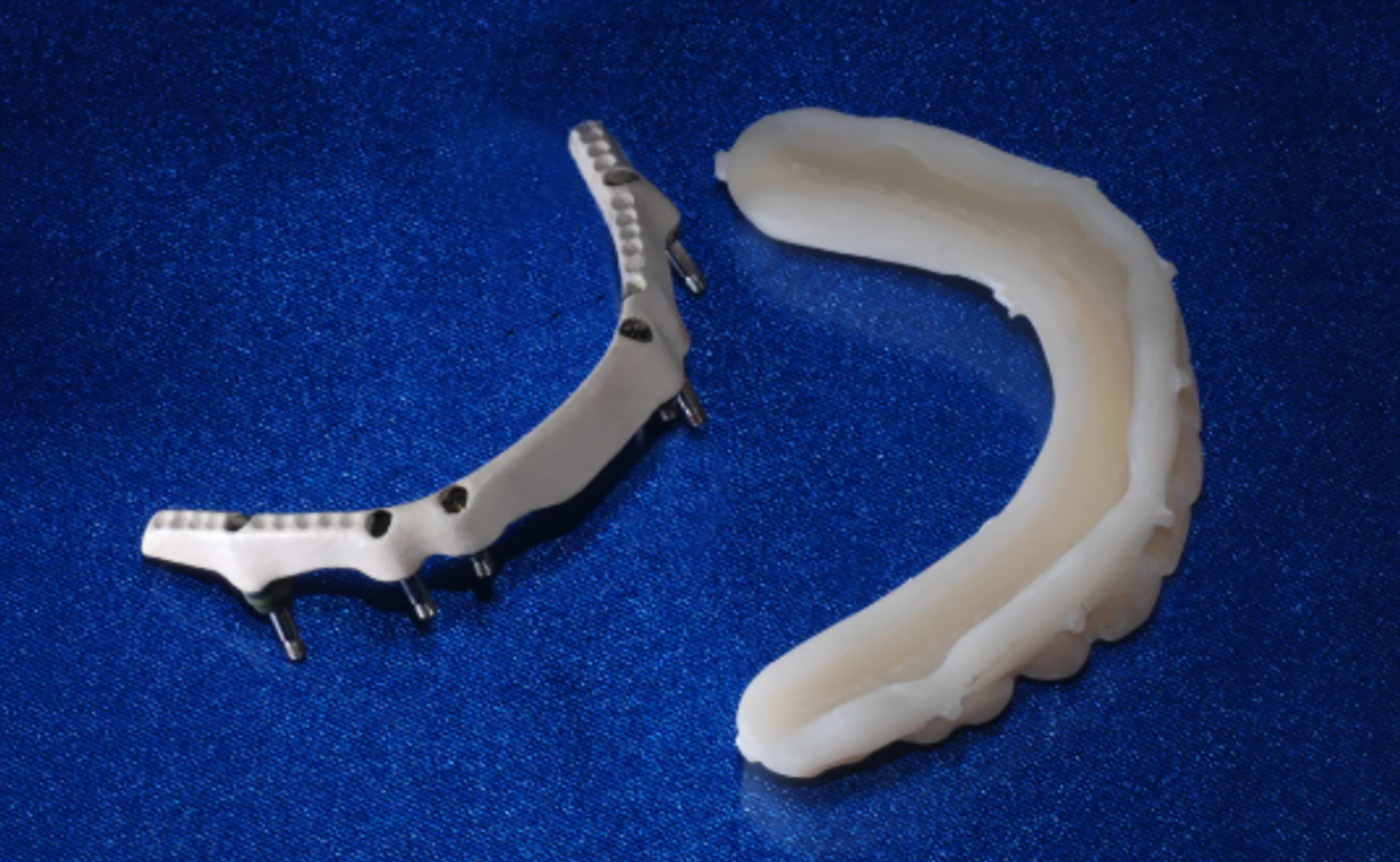

Burbank Dental Lab’s SmartComposite combines milled (nickel and beryllium-free) Cobalt-Chromium (Co/Cr) and Milled Monolithic Composite.

The first step in the process is to set up the dentures. After the set-up is confirmed and approved, we fabricate the milled Co/Cr substructure and the milled hybrid composite overlay. Co/Cr substructures can be designed to connect directly to the implant/fixture or to multi-unit abutments.

After opaquing and etching the Co/Cr frame, the two components are bonded together. As the final step in creating a SmartComposite® Hybrid, the pink tissue composite is added and polished by hand.

Ideal Applications of the SmartComposite Hybrid

The SmartComposite Hybrid is optimally suited for full-arch restorations or large spans of missing dentition, where the interocclusal distance must be at least 13 millimeters, and the buccal to lingual distance should be a minimum of 9 millimeters. In addition, from the screw access channel, the buccal and lingual surfaces must be a minimum of 3mm thick.

When a patient’s treatment plan includes two screw-retained prosthetics, this restoration is an ideal option. When such a case arises, monolithic zirconia is often used on the maxillary and SmartComposite Hybrid on the mandible.

FREE TO DOWNLOAD – SUCCESS GUIDES

DOWNLOAD A GUIDE

SmartComposite Hybrid incorporates desirable stress relief into the system due to its stress-absorbing properties.

Distinctive Properties of SmartComposite Hybrid

The hybrid’s unique attributes make it an excellent choice for full-arch fixed implant cases, particularly where the masticatory system is nonadaptive. The SmartComposite Hybrid is easy to repair, wears similarly to natural dentition, and carries a compressive strength of over 480 MPa.

Additional notable properties include:

When restoring both maxillary and mandibular arches, pairing monolithic zirconia restorations on the maxillary with a SmartComposite Hybrid on the mandibular provides stress relief throughout the mouth

Workflow for Successful SmartComposite Hybrid Cases

Successful SmartComposite Hybrid cases depend on careful planning. More planning can result in better-placed implants, leading to desirable results and patient satisfaction. Attention must be paid to any aesthetic issues caused by bone loss, vertical clearance, and the smile line.

Additionally, a comprehensive evaluation of the oral environment is necessary, utilizing bite blocks, wax set-ups, and photographs to help guide treatment planning, material selection, and aesthetic considerations. Burbank Dental Lab can assist in providing surgical guides from various workflows to ensure optimal implant placement.

Digital and traditional workflows are both viable and successful for these cases. Post-implantation, it is vital to collect information using a conversion denture for a postoperative bite and a Kois Analyzer to record the facial midline, horizontal plane, and condyle relationship.

The steps are as follows:

This is a generalized workflow, and actual procedures can vary based on a variety of factors, including the specific requirements of the dentist and patient.

As we stride confidently towards digital dentistry, Burbank Dental Lab is at the forefront of restoring implant cases with fixed prostheses. Our implant team is among the most knowledgeable in the industry, providing extensive support when restoring these life-altering cases.

To elevate your restorative work and bring unparalleled satisfaction to your patients, consider SmartComposite Hybrid for your next implant-supported hybrid case.

Contact Burbank Dental Lab today to consult with an implant team member and see how the SmartComposite Hybrid can best serve your patients. Together, we will redefine smiles, one patient at a time.