What does it mean when the term "digital denture" is used? There is not just one single answer to that question. The reality is that workflow for a “digital denture” is dependent on what records you gather at the first appointment. While the term that we are discussing here is “digital denture,” virtually all of the workflows commonly being presented today begin with a fundamentally conventional impression and bite relationship process.

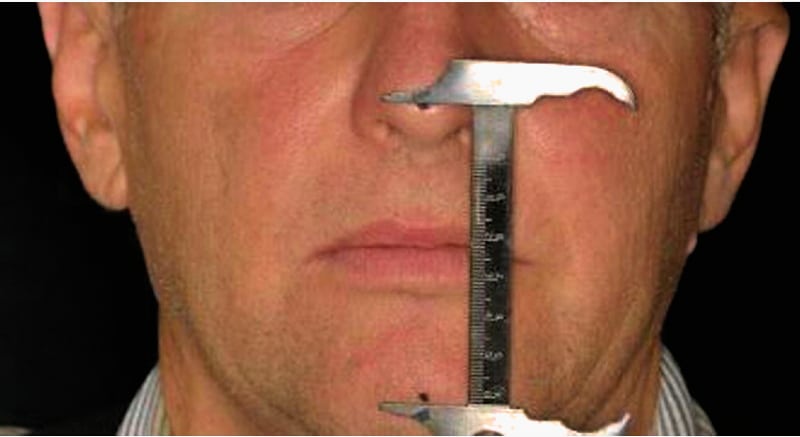

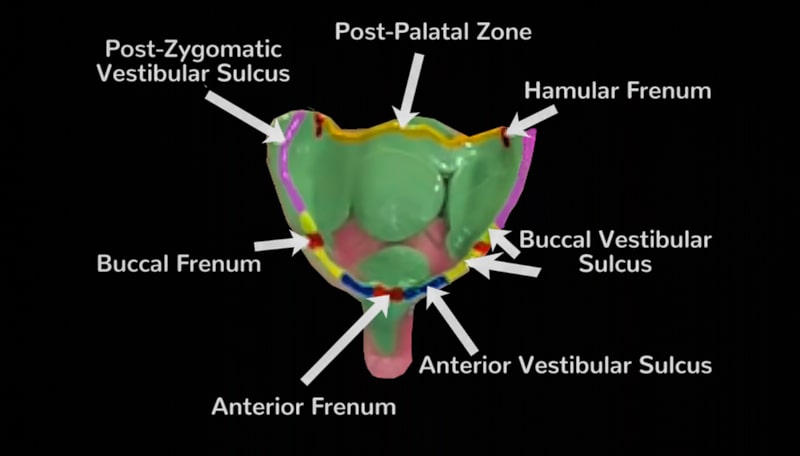

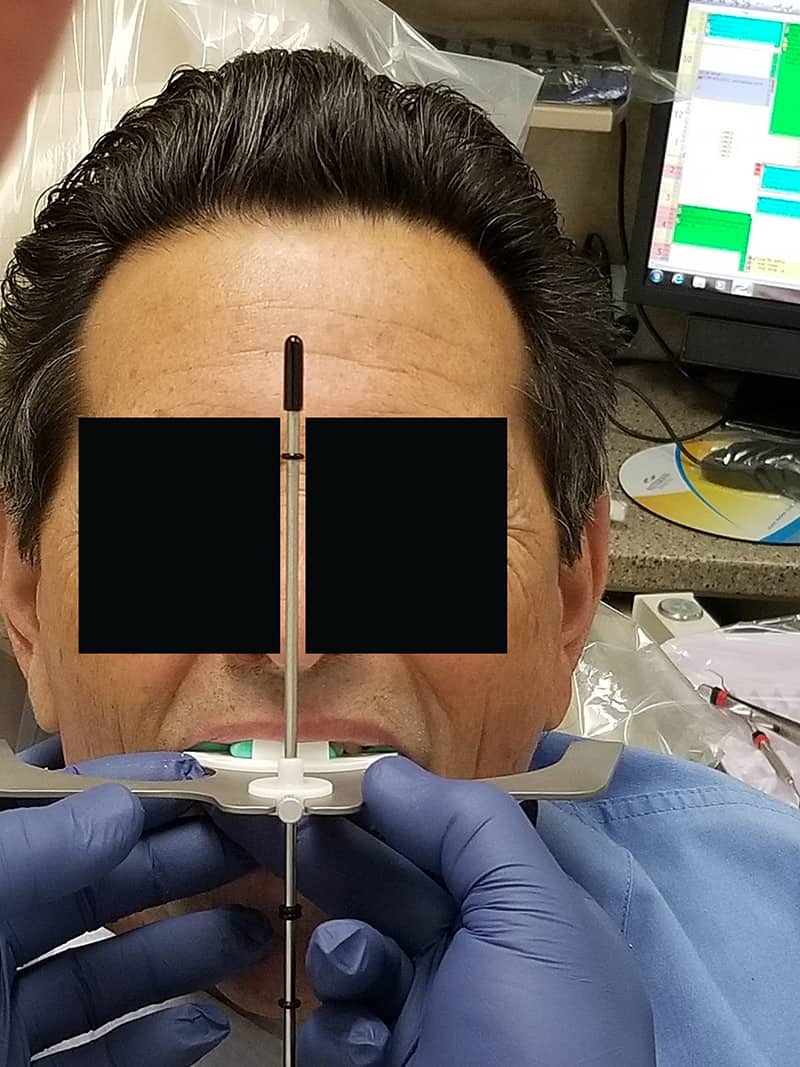

Examples of denture impression systems:

Send to the lab to fabricate teeth set-up try-in.

The lab can now articulate a duplicate denture/custom tray and proceed to set-up.

Today we have options both digital and conventional to fabricate a set-up for try-in from the records described above.

Conventional Workflow in Lab

Baseplate, wax and set denture teeth up in wax for try-in.

Digital Workflow in Lab

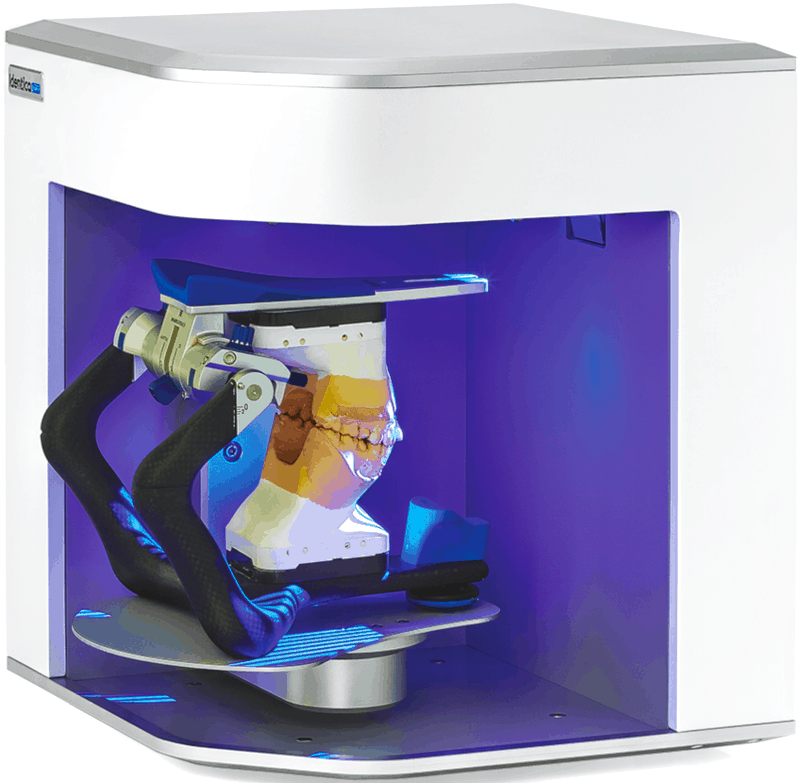

We can scan the impression, and the articulated duplicate denture, and poured models, and design the set-up via CAD systems like 3Shape, Blue Sky Plan, Exocad. When working in the digital environment we are then able to mill or print a one-piece monolithic set-up try-in.

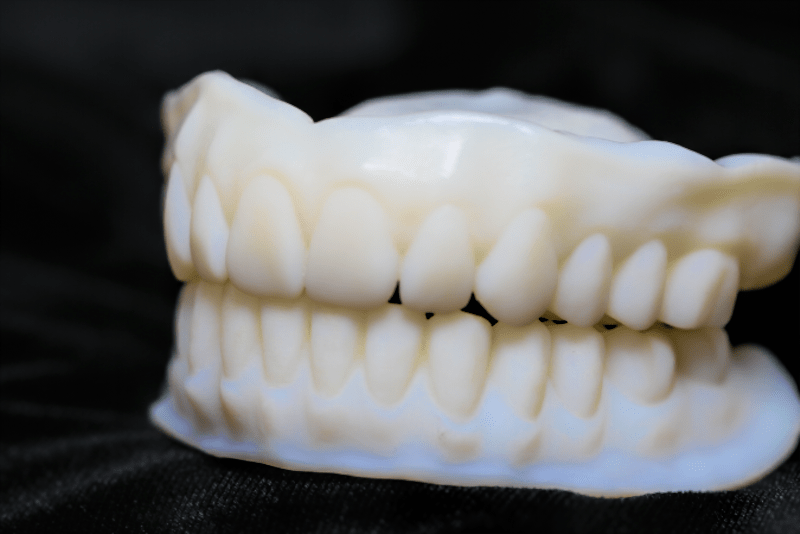

Monolithic Teeth Try-in

One very distinct benefit of milling the set-up try-in is that the fit will be virtually 100% the same as the final fit, and will be vastly superior to the fit of baseplates, or dentures processed by other methods. (More to come about milled denture in the near future.)

2nd Appointment

Try-in Teeth Set-up and Evaluate. Notate any changes and communicate directions for the lab to finish or provide a 2nd set-up try-in.

3rd Appointment