Fabrication

of the future

is here!

Burbank Dental Lab has three new state-of-the-art Carbon M2 printers. We are very excited about the options that these cutting-edge printers will allow us to offer our dental clients. Here are some of the advantages that these printers will begin to deliver to you and your dental practice.

Our New

State-Of-The-Art

3d Printers

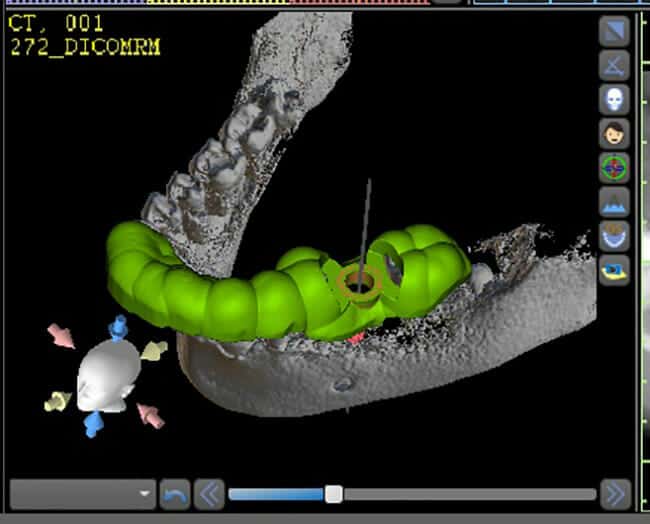

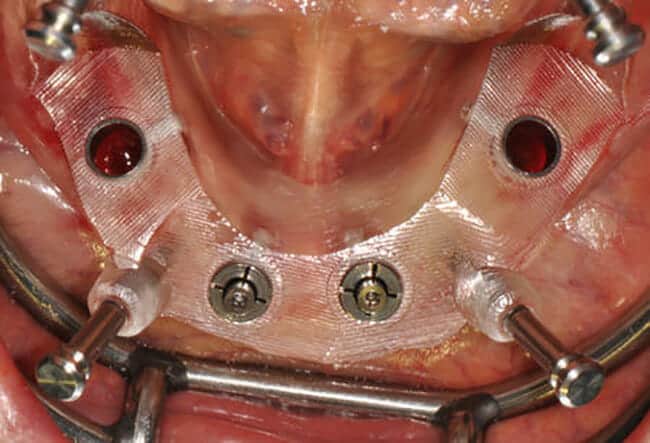

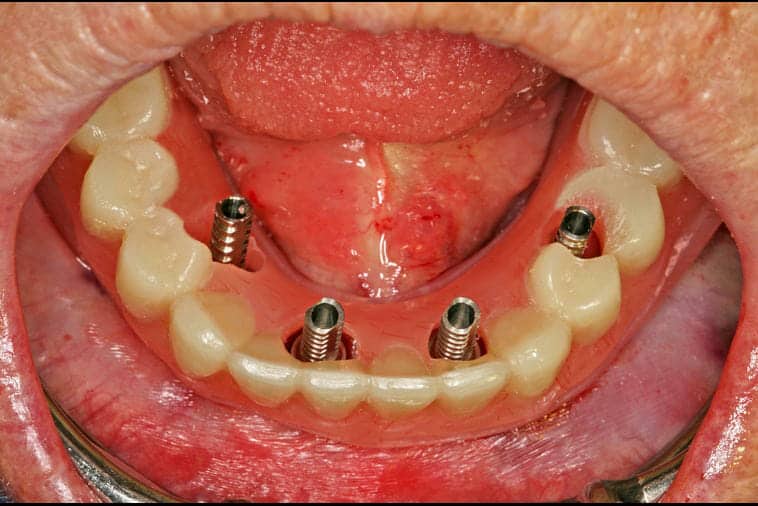

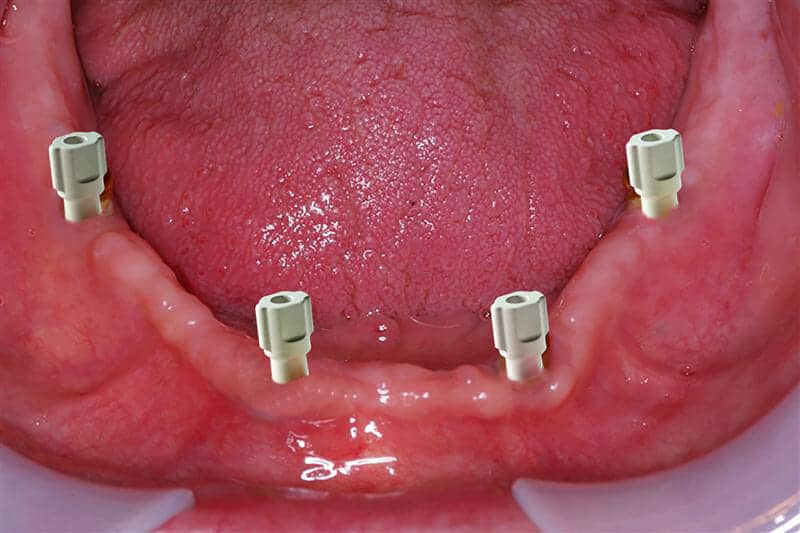

Carbon offers a highly dependable 3D manufacturing solution for many dental applications with its breakthrough Digital Light Synthesis™ technology, enabled by a wide range of dental materials.

a new baseline

for innovation

in fabrication.

Burbank Dental Lab has the next generation of Carbon DLS™. Meet our new Carbon M3 and M3 Max printers. These advanced printers enhance fabrication possibilities using Digital Light Synthesis™ technology, enabling us to provide quality and innovation for our clients.

Meet Our New

next generation of carbon DLS™

M3 Max Printers

The M3 printer is the cutting edge of DLS printing with a true 4K light engine. We save time and improve quality with Automated Print Ppreparation which ensures high-quality assurance and results.