According to the American Psychological Association (APA), stress levels in Americans have escalated in recent years. Persistent stress on individuals can lead to serious health issues over time. These health issues include a negative impact on oral health.

Stress can aggravate dental problems such as tooth fractures and cavities. This is essentially due to stress which causes many patients to grind and clench their teeth. This grinding and clenching can result in serious dental issues. The use of occlusal guards to help protect dentition has never been more important.

By absorbing extra stresses, the splint dissipates the deformation and deviations of the TMJ that happen as a result of bruxism. Orofacial structures can be protected from damage with occlusal appliances like mouth guards or bite splints. There are different types of these appliances and their uses vary.

In addition to providing dental products that meet the needs of clinicians, Burbank Dental Lab is a leading innovator in the dental industry. To keep this role, Burbank Dental Lab is committed to researching systems, technologies, and materials — and developing proprietary technologies. As a result, the research and development team at Burbank Dental Lab set out to find a next-level occlusal guard. In this case, the property of KeySplint material was combined with the technology of Carbon3D printing.

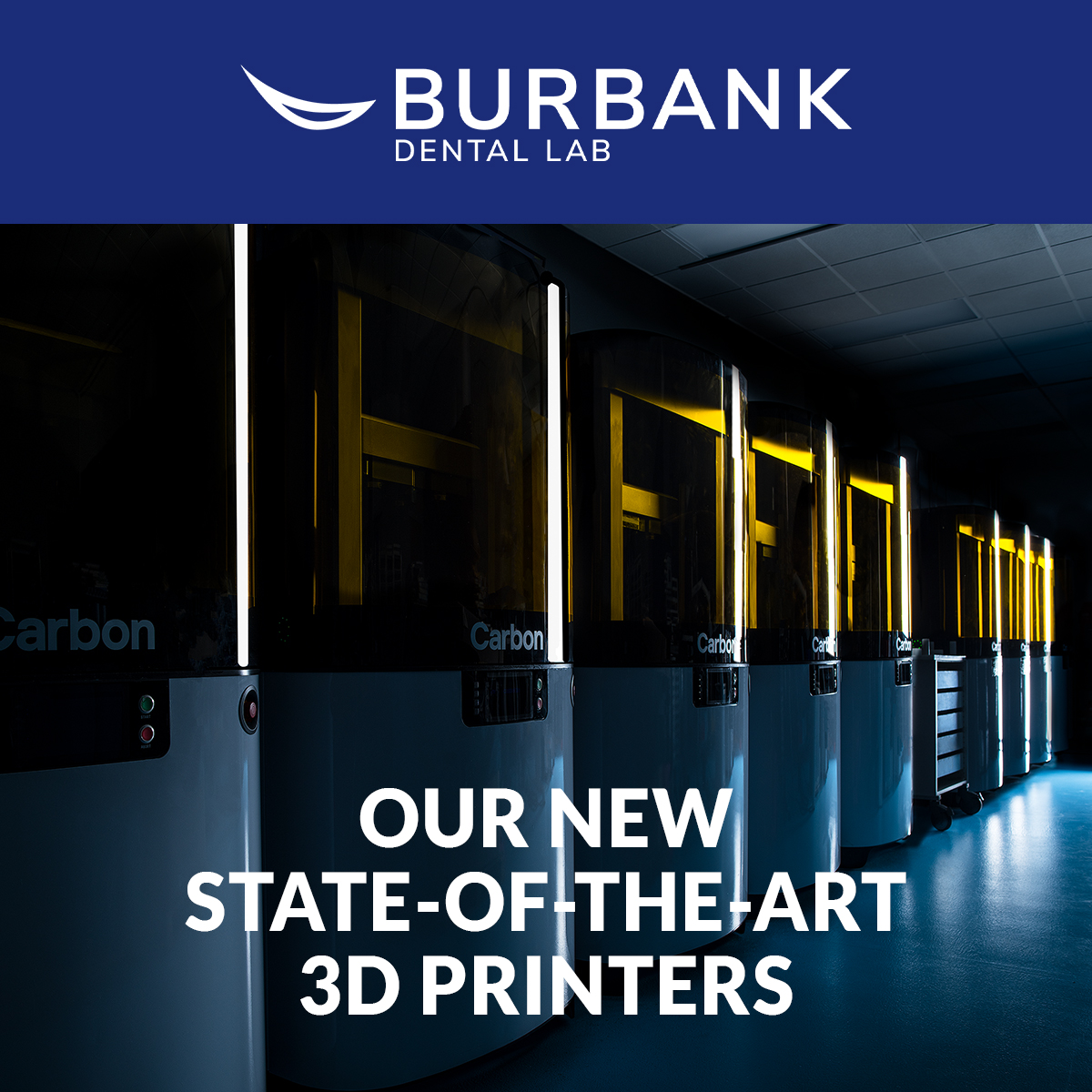

Carbon M2 Printer Technology

One of the most accurate 3D printers available (/-50um) is the Carbon M2 printer.

A case’s success is directly related to the manufacturing technology that delivers the highest level of output. The Carbon M2 uses the CLIP technology, resulting in amazing detail in its final output. The Carbon M2 printer’s excellent customization capabilities are used to create highly customized occlusal guards.

3D printing offers the following benefits as well:

KeySplint® and A State-of-the-Art Manufacturing Process

Next, we combined exceptional materials with a state-of-the-art manufacturing process to create a truly superior option for night guards and splint therapies. As a result of testing KeySplint in combination with 3D printing with Carbon, Burbank Dental Lab realized this product should be offered to its customers.

In comparison with other night guards available on the market, KeySplint has made tremendous advances. In particular, they are excellent at protecting against bruxism.

As with most medical devices, the key to success is patient compliance. Apart from being strong, the devices are also comfortable to wear. The comfort of these devices helps improve compliance, significantly increasing their success.

KeySplint night guards provide the following advantages:

Guards, splints, and bleaching trays can all be made with KeySplint resin.

How 3D Printing Is Revolutionizing Dentistry

KeySplint Benefits

KeySplint devices offer a wide range of benefits. These devices can be tailored to a dental practice’s specific needs. Traditional impressions are converted into digital files. Alternatively, scans can be taken using an intraoral camera. The information is then sent to the lab where a digitally designed appliance is created with the help of the design software until it conforms to the specifications of the case.

If any possible issues arise while designing, the designer can discuss them with the clinician. Once the design is complete, a 3D printer such as a Carbon M2 printer is used to print the device.

Here is how it is done:

KeySplint Benefits (Continued)

Capturing accurate data is crucial to case success. Here are some best practices to follow for optimizing a digital scan to ensure success.

A typical digital workflow looks like this:

Since the mandibular and maxillary arches are captured digitally, there is no need to fabricate a working model. Occlusal guards can be designed entirely in the virtual realm. This includes taking into consideration any undercuts that need to be blocked out to allow for the path of insertion.

The next step involves creating a virtual shell to allow for proper coverage of the teeth.

KeySplint Workflow

Once the parameters have been met and the guard has been designed an .STL file is created. This file is then processed to a 3D printer such as the Carbon M2 printer where the appliance is printed out according to the file specifications.

In addition to digital impressions, Burbank Dental Labs accepts analog impressions. If the impressions are analog, Burbank Dental Lab will convert them into digital data in order to design and print the case digitally.

In dentistry, occlusal guards are recommended for a variety of reasons. Due to increasing stress in everyday life, patients need to protect their natural teeth, restorations, or both. The most valuable service we can provide is helping to eliminate patients’ pain. As dental treatment technology advances, the industry will be able to offer better options in terms of systems, materials, and technologies. Burbank Dental Lab takes advantage of existing and emerging technologies in keeping with one of its core values. This ensures that clinicians working with us have access to the newest developments. Get more information about our appliances by contacting us.

In addition, while they work to adapt to the new device, most patients also report experiencing excess saliva production. Once they become accustomed to wearing the device, the discomfort will dissipate.

Call or chat today to find out more about our appliances at Burbank Dental Lab.