A Step-By-Step Workflow

Following is a simplified step-by-step workflow for an edentulous implant case, within a digital workflow.

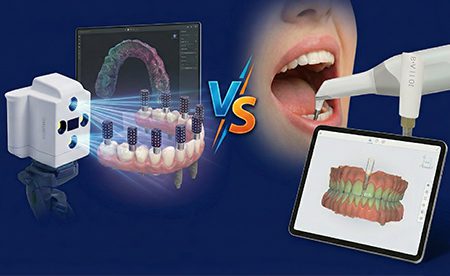

In today’s world, it is possible to do virtually all major steps of implant prosthetic work in a digital workflow. However, it is usually carried out drifting in and out of a truly digital workflow, and we are still reliant on the traditional procedures in many instances.

Each clinician should make workflow decisions based on patient needs and practice efficiency for each case individually.

Digital Workflow Procedures for Edentulous Implant Cases

1. Create an ideal denture set-up, either from the current denture or new set-up.

The initial steps in a digital workflow for an edentulous case are essentially the same as a conventional workflow.

There are two possible starting places for any given edentulous implant case. In either situation, the goal of the initial sequence of records is to establish the desired vertical, smile line, tooth position, occlusion, and phonetics.

In both cases, it is important to take a PVS to reline impression in the duplicate denture or new denture set-up.

REQUEST YOUR FREE IMPLANT SUCCESS GUIDE BELOW

Success Guides

2. Fabricate CT Scanning Appliance. (Figure 3)

Once an ideal denture set-up is established it is then used as the basis for a CT scanning appliance.

Important design elements for the CT Scanning Appliance:

Optically scan the appliance with the stone base prior to separation, and optically scan the model after separation.

3. The CT Scanning Appointment

Perform the scan with the CT scanning appliance in the mouth. (Figure 6)

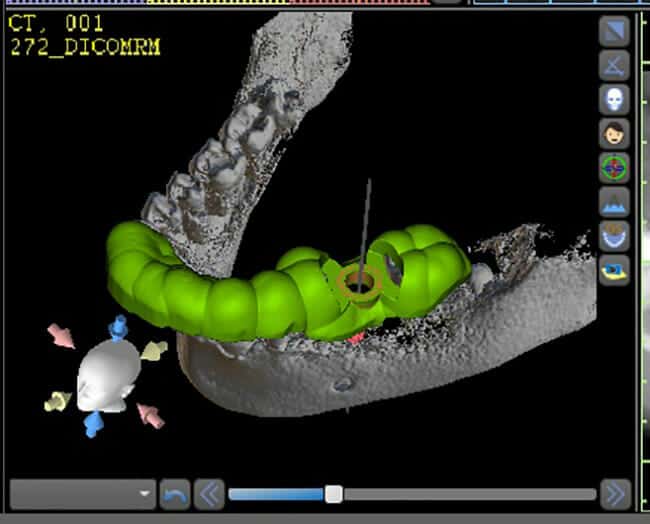

4. Surgical Planning

5. Guided Surgery Appliance Design

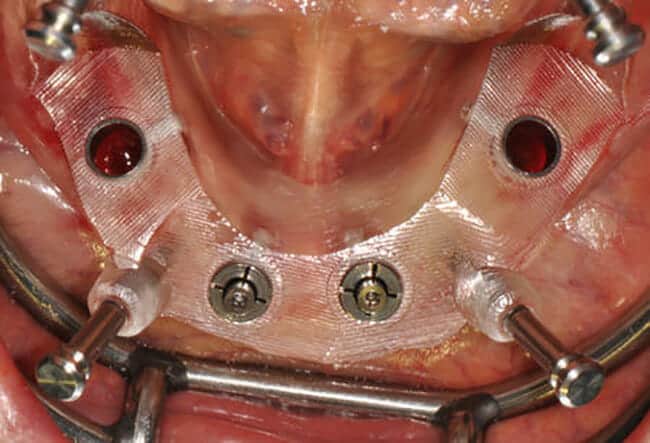

6A. Surgical Appointment

6B. Surgical Appointment - Immediate Provisionalization

Conversion denture can be pre-fabricated using the digital implant planning software in a few different ways: Figure 10

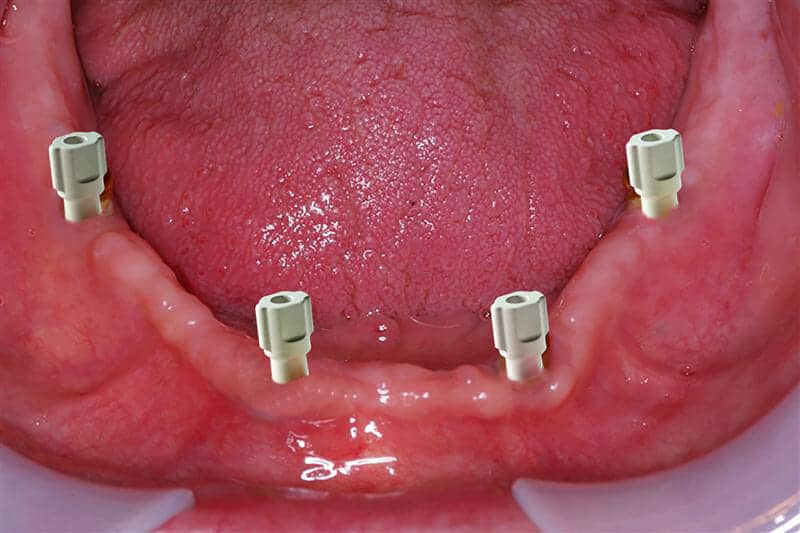

The titanium cylinders are seated, and then the prosthetic is placed over the top and tacked down. The prosthetic is removed and perfected for delivery during the surgical appointment.

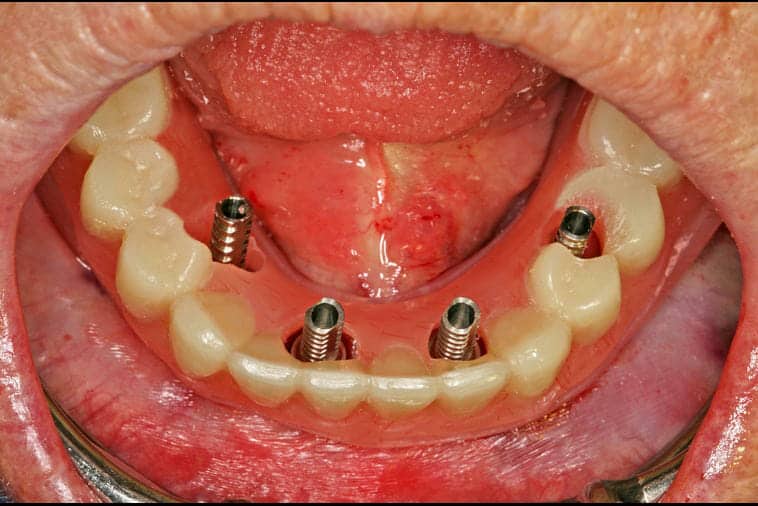

7. Digital impression appointment for PMMA provisional prosthetic

8. PMMA provisional designed and fabricated (Figure 12)

The lab merges the scan body .stl, the model scan, and the appliance scan within the design software. Once the digital merge is complete the PMMA prosthetic can be perfected and milled.

It should be noted that intra-oral full arch impressions using digital scan bodies are not 100% dimensionally accurate. Full arch prosthetics that are fabricated from an intra-oral scan are not guaranteed for fit. In these cases, it is always best to deliver a PMMA provisional that is cemented to the titanium cylinders in the mouth. This will reduce the potential for fit problems. Once the PMMA provisional is delivered and the patient has lived with it for a period of time, the PMMA provisional can be used to scan and copy mill the final prosthetic restoration.

9. Final restoration delivery

Final restorations can be fabricated from a scan and copy mill of the tested and approved provisional can be delivered in a variety of materials for the final restoration.

The digital workflow is a rapidly changing environment. In this article we have reviewed certain steps; however, there are other workflows. It is always best to consult with Burbank Dental Lab prior to beginning a workflow on a complex case to assure that the current procedures used will assure you and your patient of the best results.

Burbank Dental Lab has the technology to assist you in the process of creating full arch prosthetics and the expertise to partner with you in the success of your cases.